شرح نسيج الدنيم: الغزل والعملية

الوقت المقدر للقراءة: ~2 دقيقة

مقدمة عن قماش الدنيم

يتجاوز الدنيم كونه قماشًا، فهو يُجسّد أسلوب حياة عصريًا وعلامة مميزة في عالم الموضة، ويُعدّ عنصرًا أساسيًا في الأناقة. هل فكرت يومًا في تركيب قماش الدنيم أو عملية تصنيعه؟ ستستكشف هذه المقالة عالم الدنيم الرائع من خلال وصف تركيبه وعدد خيوطه، وشرح خطوات التصنيع التي تُنتج هذه المادة الأيقونية.

من ماذا يصنع قماش الدنيم؟

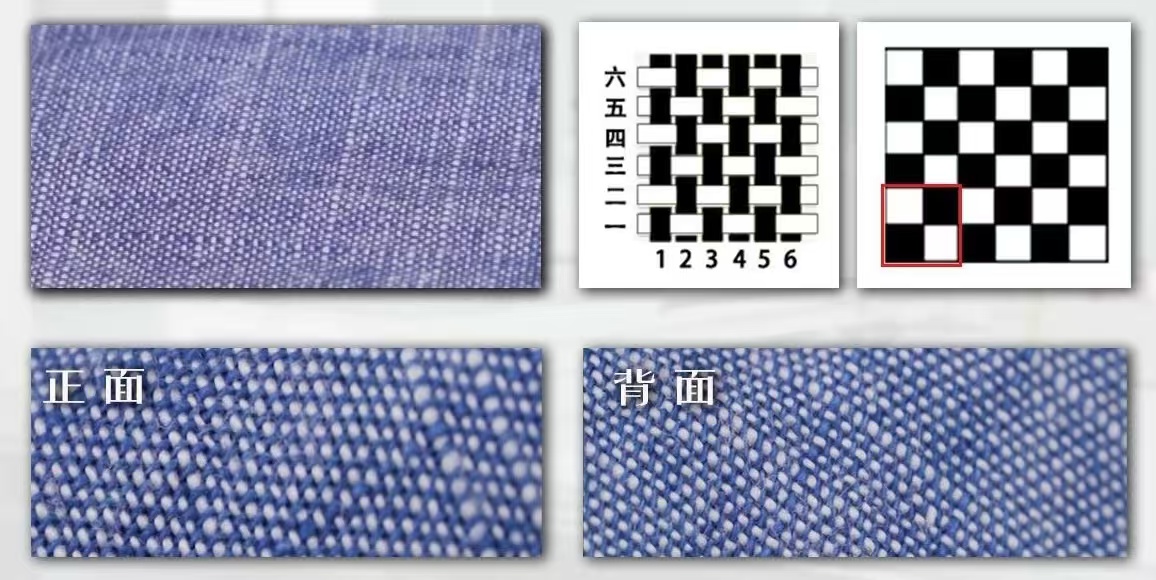

يتكون أساس الدنيم من القطن، لكن بعض منتجات الدنيم الحديثة تمزج هذه المادة مع البوليستر أو الإيلاستين لتوفير خاصية التمدد. يحقق قماش الدنيم قوته المميزة من خلال نسج مائل، حيث تتقاطع خيوط السدى (عادةً ما تكون مصبوغة باللون النيلي) مع خيطين أو أكثر من خيوط اللحمة (غالبًا ما تُترك غير مصبوغة) لتكوين النمط القطري. إن الجمع بين القوة والملمس في قماش الدنيم يجعله المادة المفضلة للجينز والسترات وتنجيد الأقمشة.

نسج عادي

دور عدد الخيوط في الدنيم

يُحدد قطاع صناعة الغزل عدد الخيوط من خلال قياس سُمك الخيوط، والذي يُحسب الكتلة لكل وحدة طول. يقيس قطاع الغزل سُمك الخيوط باستخدام نظام عد القطن الإنجليزي المعروف باسم "Ne". يُحدد هذا النظام دقة الخيوط من خلال أرقام Ne أعلى. يستخدم إنتاج الدنيم أعداد خيوط تتراوح بين Ne 4 للخيوط السميكة الثقيلة وNe 20 للخيوط الرقيقة، بينما يستخدم المُصنّعون خيوطًا تصل إلى Ne 200 لإنتاج خيوط فائقة النعومة.

تشير ملصقات الدنيم "7×7" أو "6×6" إلى عدد خيوط السدى واللحمة على التوالي. قماش الدنيم المصنوع من خيط Ne 4 يُنتج قماشًا ثقيلًا يناسب الجينز المتين، بينما يُنتج خيط Ne 20 قماشًا خفيفًا مناسبًا للفساتين والقمصان الصيفية. يُحدد عدد الخيوط متانة منتجات الدنيم وملمسها، ولكن معظم العلامات التجارية تتجنب الكشف عن هذه المعلومة.

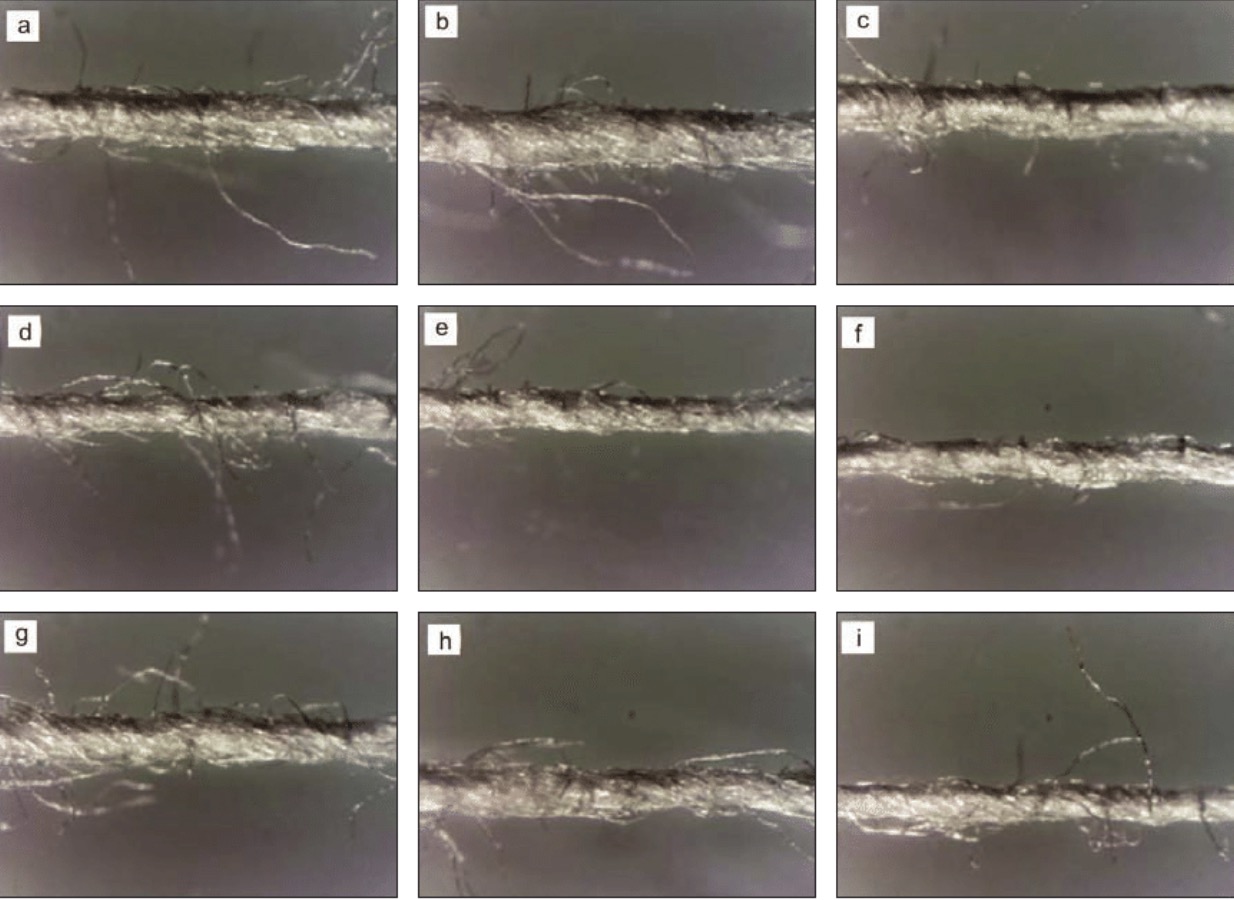

عينات الغزل التي تم غزلها بأعداد مختلفة وضغوط فوهة مختلفة

كيف يُصنع الدنيم؟ عملية الغزل

تبدأ أولى خطوات إنتاج الدنيم في قسم الغزل. إليكم شرحًا مبسطًا:

- تحضير القطن:تتضمن العملية الأولية لإعداد القطن تنظيف القطن الخام الذي يتم تمشيطه إلى شرائح تبدو مثل الحبال الطويلة.

- الغزل:تحوّل عملية الغزل الخيوط الصغيرة إلى خيوط باستخدام تقنيات الغزل الحلقي، مما يُنتج خيوطًا متينة وموحدة مناسبة لإنتاج الدنيم. يُحدَّد عدد الخيوط في هذه المرحلة من الإنتاج.

- الصباغة:تتلقى خيوط السدى عملية الصباغة باستخدام صبغة النيلي، لكن خيوط اللحمة تبقى غير مصبوغة.

- النسيج:يتم نسج خيوط السدى المصبوغة باللون النيلي مع خيوط اللحمة غير المصبوغة باستخدام أنوال ذات بنية مائلة.

تؤدي عملية التصنيع إلى أن يكون لقماش الدنيم مظهره الأزرق والأبيض مع نسيج كثيف يؤدي إلى مظهره المميز سواء تم بيعه كقماش خام أو منتجات نهائية.

لماذا عدد الخيوط مهم؟

اختيار عدد الخيوط يُحدد أكثر من مجرد الوزن، إذ يُحدد مستويات الراحة والمتانة، بالإضافة إلى نتائج التصميم. على سبيل المثال:

- الدنيم الثقيل (Ne 4–10):رائع للسترات المنظمة أو الجينز ذو الطراز القديم.

- الدنيم الفاتح (Ne 12–20):مثالي للقطع الناعمة القابلة للتنفس مثل التنانير أو قماش الدنيم للبيع في المشاريع الإبداعية.

يصبح اختيار قماش الدنيم لمشروعك المنزلي أو شرائه أسهل عندما تفهم معلومات عدد الخيوط.

خاتمة

ينشأ قماش الدنيم من مصادر قطنية تقليدية، بينما تُضفي عمليات غزله ونسجه طابعًا مميزًا من خلال أساليب التصنيع الحديثة. في المرة القادمة التي تبحث فيها عن قماش الدنيم بالياردة أو ترغب في فهمه، انتبه جيدًا لعدد الخيوط وطرق التصنيع المستخدمة.