Дефекты джинсовой ткани и контрольный список осмотра

Введение

В современной моде деним — это больше, чем просто культовый текстиль. Он олицетворяет качество, экологичность и потребительский опыт. Компания LYDenim, специализирующаяся на производстве премиального денима, предлагает «Руководство по оценке качества и закупкам денима», которое поможет покупателям оценить ткань по тактильным ощущениям, визуальному восприятию и техническим критериям. В этой статье обобщены основные идеи и передовой опыт LYDenim, чтобы предоставить вам практическую систему проверки и закупок, гарантирующую соответствие ваших покупок денима высоким стандартам долговечности, внешнего вида и ценности.

Производство джинсовой ткани

1. Стандарты и тенденции отрасли: общие сведения

- Типы тканей в LYDenim: Они предлагают хлопок 100%, смеси хлопка и спандекса, различные виды отделки, от легкого до плотного денима — каждый из которых разработан для определенных случаев использования.

- Растущий спрос во всем миреПокупатели всё больше ценят стойкость цвета, устойчивость к стирке (усадка/выцветание), экологическую и химическую безопасность, а также возможность отслеживания происхождения. LYDenim подчёркивает соответствие международным стандартам качества и экспортирует свою продукцию на рынки ЕС и США.

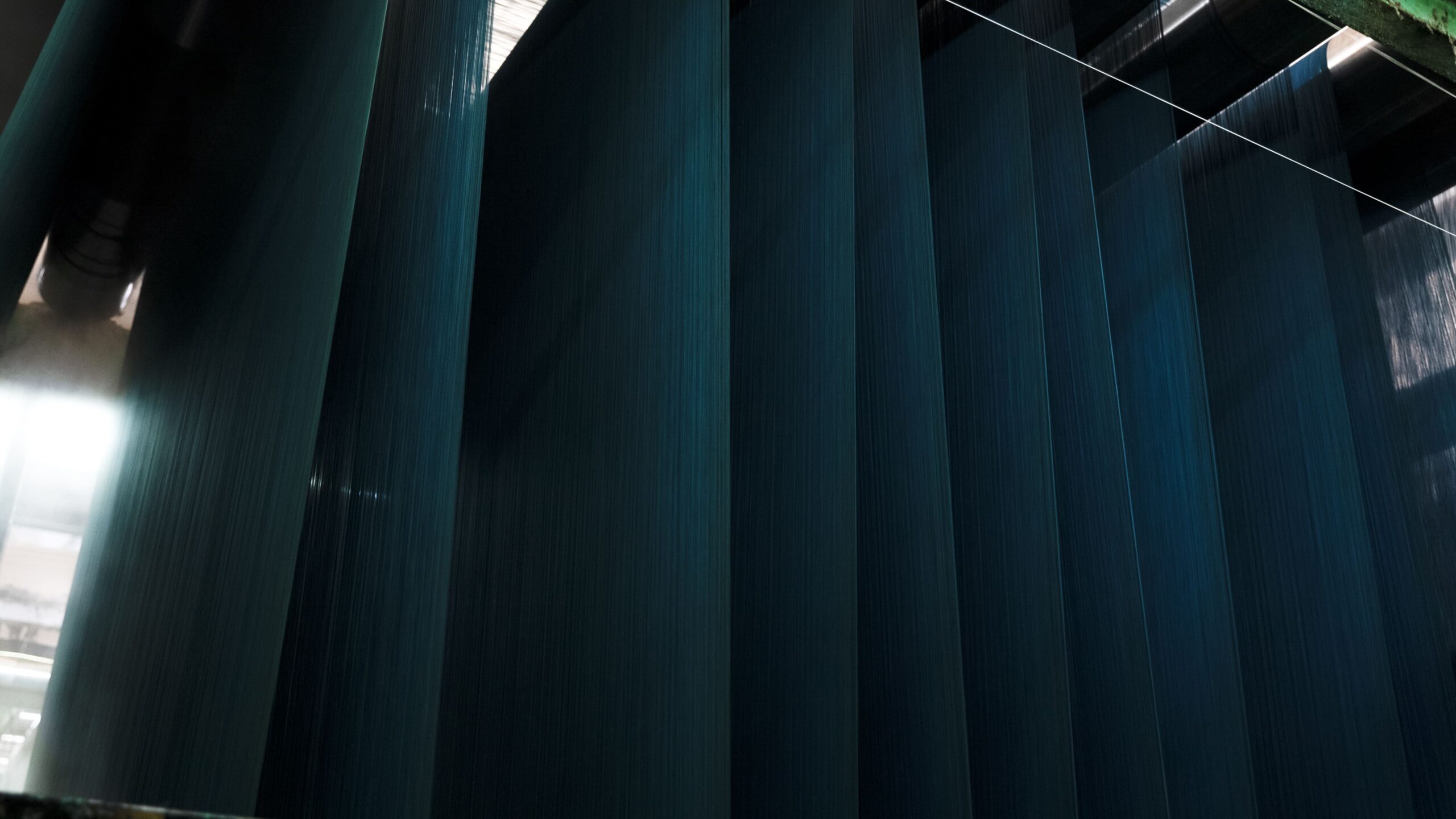

Окрашивание

- Ожидания относительно прикосновений и старения: Качественные ткани оцениваются не только по внешнему виду и ощущениям, но и по тому, как они стареют, выцветают и ощущаются со временем. Руководство LYDenim подчеркивает тактильную оценку (толщина, плотность плетения, эластичность) как показатели долговечности.

Деним

2. Процесс проверки и обязанности

- Пункты досмотра: фаза образца → после ткачества → после окраски/отделки → оценка после стирки → перед раскроем/шитьем → конечный продукт / перед отправкой.

Пункты досмотра

- Роли: контроль качества поставщика, контроль качества покупателя, тестирование третьей стороной при необходимости (особенно для крупных/партионных заказов).

Контроль качества ткани

- Дискретизация и частота: Используйте стандарты, основанные на весе (в унциях), плотности ткани, эластичности и т. д., чтобы определить подходящий размер выборки. LYDenim проводит оценку как на ощупь/визуально, так и техническими тестами.

- Система стандартов: К основным параметрам относятся вес ткани (унций на кв. ярд или г/м²), плотность переплетения, спандекс %, наличие или отсутствие кромки, тип красителя (индиго, серный, реактивный), методы отделки и т. д.

3. Классификация дефектов

Ниже приведены типы дефектов, взятые из LYDenim + отраслевой практики, полезные для практических проверок.

| Категория | Распространенные дефекты | Источник Фаза / Воздействие | Инспекция / Допустимые пределы |

|---|---|---|---|

| Плетение | Порванные нити основы/утка; толстые клубки; неровное переплетение; следы от ткацкого станка | Этап ткачества; если качество пряжи или настройка ткацкого станка плохие | Визуальный контроль + проверка под микроскопом; пороговое значение дефектов на метр; для изделий с кромкой очень низкий допуск |

| Окрашивание и изменение оттенка | Неравномерное окрашивание; несоответствие цветов в партии; растекание краски или неровные края; плохая стойкость цвета во влажном и сухом состоянии | Фазы крашения/окисления/ополаскивания | Сравните стандартные образцы; тесты на истирание влажным/сухим способом; измерьте разницу в цвете с помощью оборудования; сравните края с центром |

| Мойка и отделка | Усадка; выцветшие пятна; следы от воды; деформация формы после стирки | Этапы мойки/химической обработки/отделки | Тест образца перед стиркой; измерение размеров до и после; оценка поверхности и цвета после стирки; проверка остатков химикатов (pH, отбеливателя и т. д.) |

| Проблемы с эластичным денимом | Потеря эластичности/плохое восстановление; волнистость швов; закручивание краев; открытые или разорванные эластичные волокна | Состав смеси; операции шитья и стирки | Испытание на восстановление после растяжения; испытание на растяжение при шитье; многократные циклы стирки; проверка отделки краев |

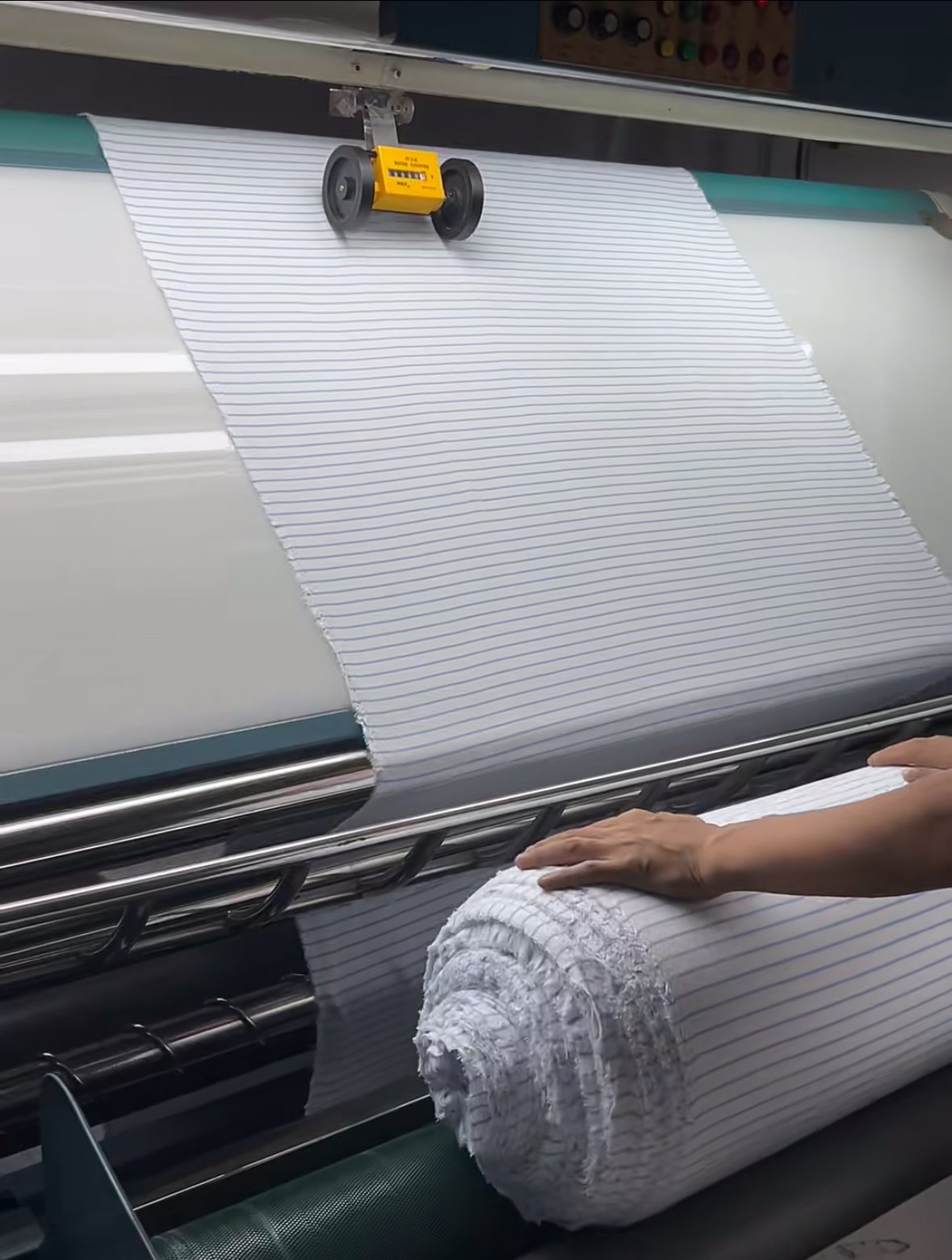

| Поверхностные и структурные дефекты | Зацепки, пух, дырки, проколы; перекосы/искривления; неровные края | На протяжении всего производства, а также обработки, хранения и транспортировки | Визуальный осмотр при стандартном освещении; полный рулон разворачивается для осмотра центра и краев; проверка упаковки/хранения |

| Качество изготовления и отделка | Порванные нитки; пропущенные стежки; слабые/плохо закрепленные пуговицы/молнии; коррозия металла | Этап шитья; во время носки и стирки; отделка | Испытания на прочность; проверка крепления отделки; испытание на коррозию при стирке; проверка качества швов |

| Рулон / Обработка / Доставка / Хранение | Слишком тугие рулоны; отклонения по длине или ширине; повреждения при транспортировке; повреждения от влаги; загрязнение | Этап прокатки, упаковки, отправки, хранения | Осмотрите рулоны по прибытии; распакуйте и проверьте на наличие складок/отметин; проверьте размеры рулона; влажность при хранении и качество упаковки; четкую маркировку и информацию о партии. |

4. Количественные стандарты и инструменты

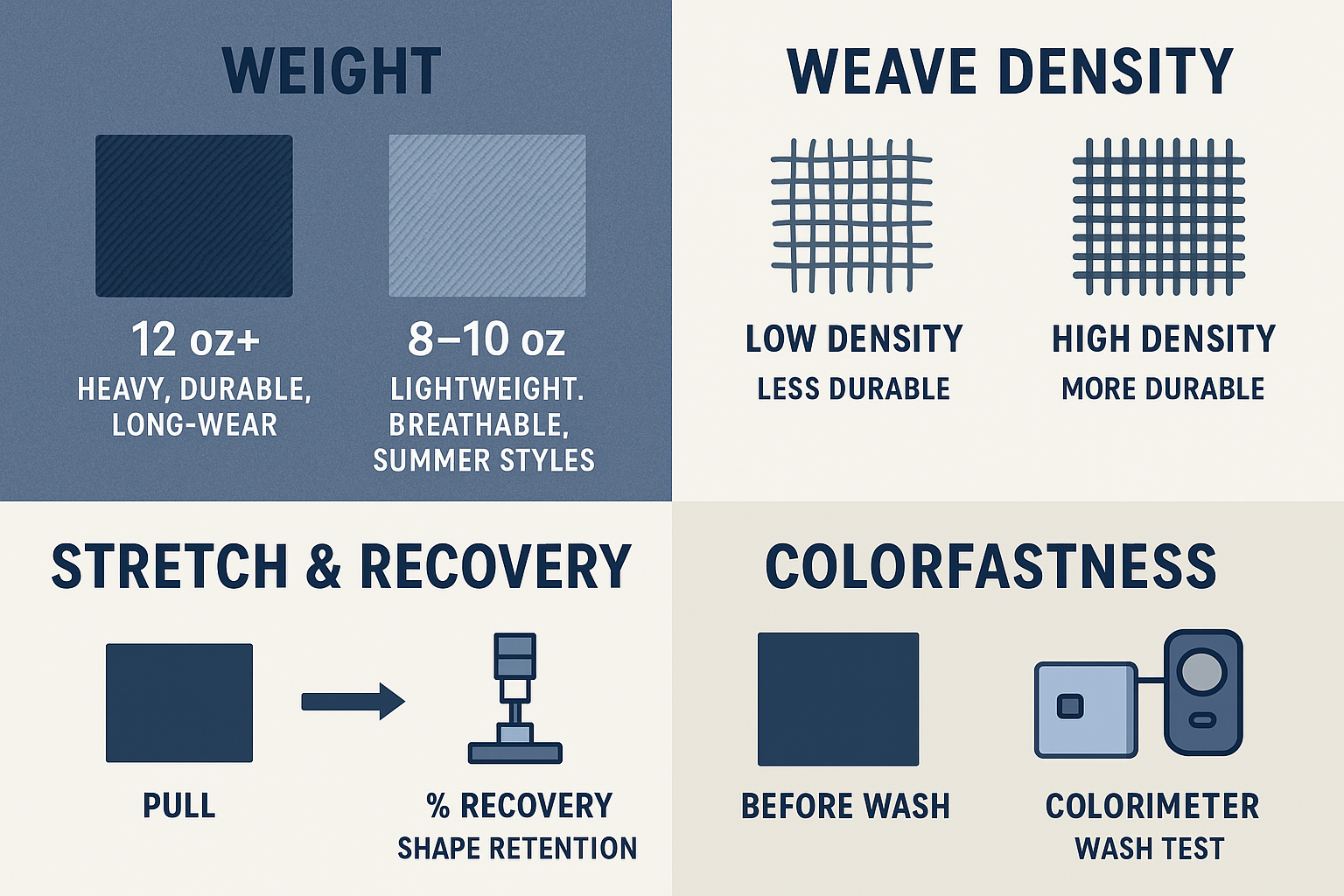

- Вес контрольные показатели: Джинсовая ткань плотностью ≥12 унций для интенсивного/длительного ношения; более лёгкая (8–10 унций) для тёплого климата или лёгких моделей. LYDenim использует схожие критерии.

- Плотность плетения/количество нитей: Более высокая плотность = меньше искажений, лучшая долговечность.

- Растяжка и восстановление %: Для эластичной джинсовой ткани проверьте, насколько хорошо ткань восстанавливает первоначальную форму.

- Стойкость цвета и изменение цвета при стирке: Тесты на истирание влажным/сухим способом; тесты на искусственную стирку; сравнение цвета до/после с помощью колориметра.

- Необходимые инструменты: Микроскопы или увеличительное стекло; колориметр; машина для испытания на растяжение/вытяжку; стиральная машина (лабораторная или промышленная); условия контроля температуры/влажности.

Количественные стандарты и инструменты

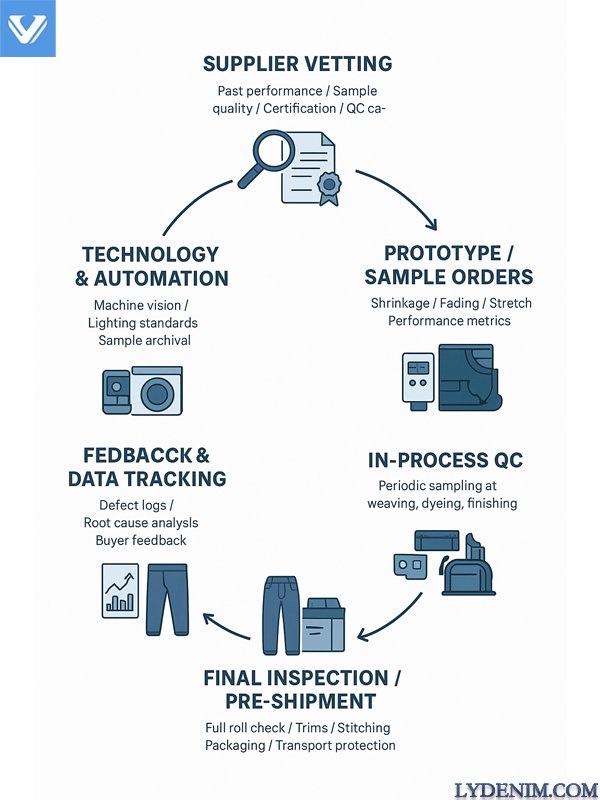

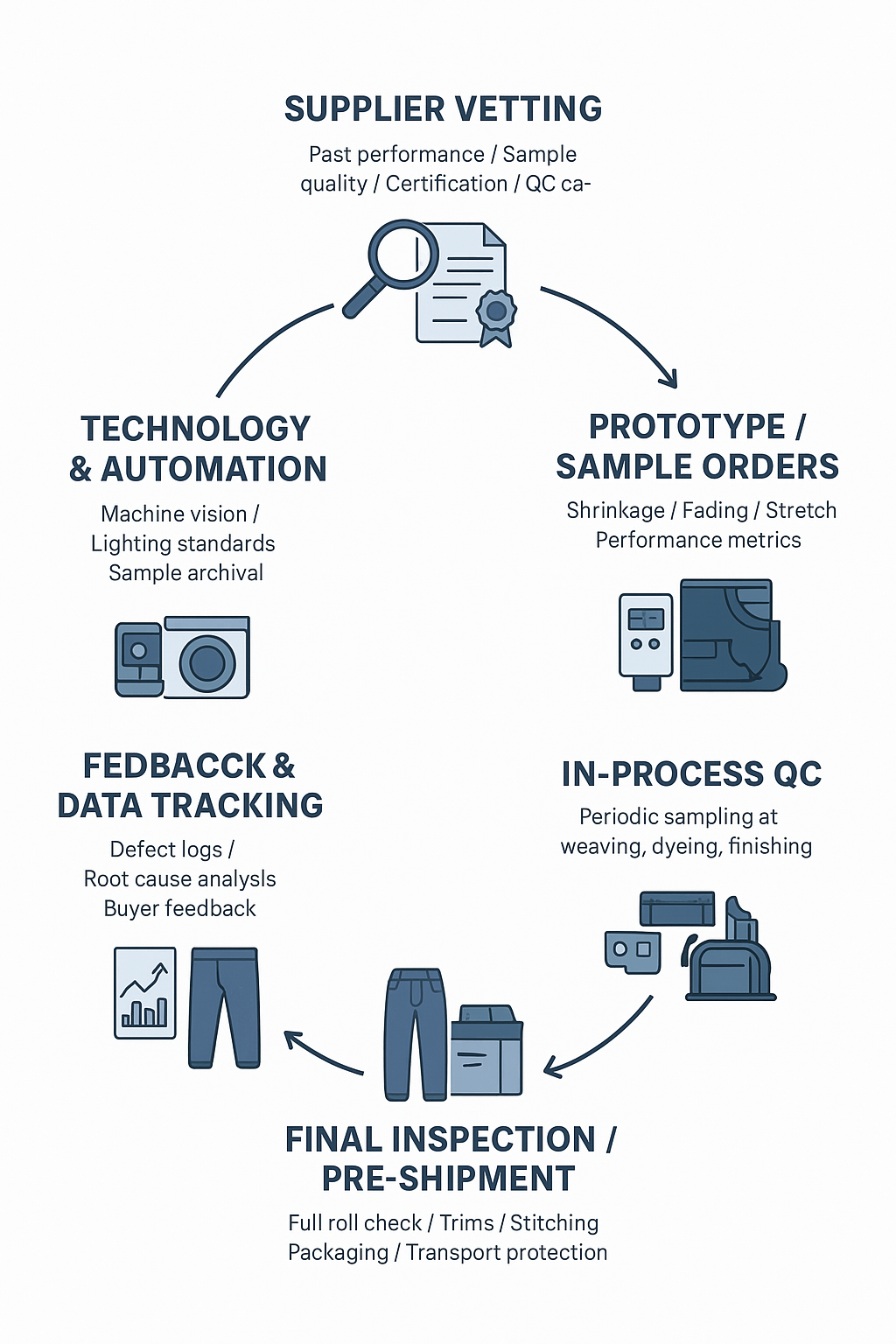

5. Рабочий процесс контроля качества и постоянное совершенствование

- Проверка поставщиков: Оцените прошлые результаты, качество образцов, сертификацию, возможности контроля качества.

- Заказы прототипов/образцов: Проверьте все критические показатели производительности: усадку, выцветание, растяжение и т. д.

- Контроль качества в процессе производства: На этапах ткачества, крашения, отделки — периодический отбор проб для выявления тенденций дефектов.

- Окончательная проверка / перед отправкой: Полная проверка рулона и продукции; отделка, сшивание, упаковка, защита при транспортировке.

- Обратная связь и отслеживание данных: Ведение журналов учета уровня дефектов; анализ первопричин; корректирующие действия; учет отзывов покупателей/пользователей.

- Технологии и автоматизация: Используйте визуальный осмотр, возможно, машинное зрение/распознавание изображений для выявления дефектов поверхности; обеспечьте стандарты освещения; архивируйте образцы.

Контроль качества

6. Контрольный список проверки покупателя (практический и измеримый)

| Проверить пункт | Стандарт качества / Приемлемый предел | Инструмент/Метод | Ответственная сторона |

|---|---|---|---|

| Вес ткани | ≥12 унций или согласно спецификации | Масштаб/стандартная ссылка | Поставщик + Покупатель (этап образца) |

| Плотность плетения | Нет видимых отверстий/пробелов в переплетении; отклонение количества нитей ≤ ±указанному | Микроскоп/измеритель плетения | Контроль качества в процессе производства |

| Постоянство цвета | Цвет ΔE ≤ порога; совпадение цветов партии; минимальное различие между краем и центром | Колориметр + визуальный тест освещения | Красильный цех + проверка покупателя |

| Восстановление после растяжения | Восстановление ≥90% после указанного растяжения (пример) | Машина для растяжки/восстановления | Заказы на эластичную ткань |

| Усадка при стирке | ≤Указанный процент (например, ≤3%) | Лабораторная мойка + измерение | Предварительная отгрузка/Покупатель |

| Дефекты поверхности | Максимальное количество дефектов на метр (оборванные нитки, зацепки и т. д.) | Визуальный + лупа при стандартном освещении | Окончательная проверка |

| Качество стежка и отделки | Никаких пропущенных стежков; надежная отделка; металлические детали не ржавеют после стирки | Тест на стирку + тест на нагрузку + визуальный осмотр | Контроль качества продукции |

| Состояние рулона/упаковки | Ровная форма рулона; отсутствие складок и влаги; четкие этикетки; защитная упаковка | Осмотр по прибытии | Этап получения товара покупателем |

Заключение

Выбор высококачественного денима — многогранная задача, включающая не только внешнюю привлекательность, но и эксплуатационные характеристики, долговечность, устойчивость к старению и целостность цепочки поставок. Руководство LYDenim предоставляет надежную основу, охватывающую вес, плетение, окрашивание и отделку, но на практике закупщикам необходимо согласовывать стандарты с позиционированием своего бренда и выстраивать замкнутый цикл процесса, от закупки до проверки, отгрузки и обратной связи с потребителями. Используя количественные показатели и инструменты в сочетании с опытом и технологиями, выбранный вами деним может стать настоящим конкурентным преимуществом вашего продукта.

Услуги по настройке от LYDENIM

Мечтаете о тканях премиум-класса с выдающейся текстурой и долговечностью? Компания LYDENIM специализируется на высококачественных тканях и пошиве одежды на заказ, помогая вам воплощать творческие идеи в реальность с точностью и стилем.

🎨 Ткани на заказ

Создайте свою собственную коллекцию тканей из материалов премиум-класса LYDENIM. От роскошных хлопковых смесей до инновационных экологичных тканей — изучите цвета, плетение и отделку, которые идеально соответствуют вашему бренду или дизайнерскому замыслу. Перейти ЛИДЕНИМ чтобы узнать больше.

🛍️ Индивидуальные решения для одежды

Воплотите свои идеи в жизнь с помощью наших услуг по пошиву одежды на заказ. Будь то костюмы, стильные платья или прочная рабочая одежда, мы гарантируем идеальную посадку, непревзойденный комфорт и долговечность. Ознакомьтесь с вариантами персонализации на сайте Мьяли-Баба.

📩 Свяжитесь с нами

Есть идея проекта? Свяжитесь с нашей командой по адресу malone@lydenim.com для обсуждения индивидуальных тканей, дизайна одежды или устойчивых текстильных решений.

Воплотите свои идеи в реальность с LYDENIM — вашим надежным партнером в области инновационных, высококачественных тканей и решений по пошиву одежды на заказ.