5 Key Denim Fabric Widths for Jeans

Estimated reading time: ~5 minutes

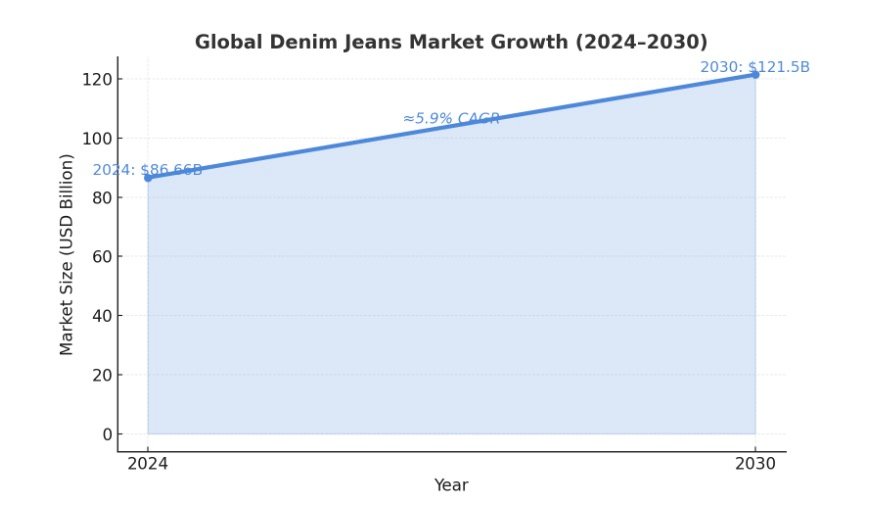

In the fast-paced world of custom jeans manufacturing, selecting the right denim fabric width is a game-changer for garment factories aiming to deliver high-quality products swiftly. With the global denim market projected to grow at a 4.4% CAGR from 2021 to 2030 (reaching $27.9 billion by 2030), efficiency isn’t just a buzzword—it’s essential for staying competitive. This guide dives into the best denim fabric width options, backed by industry data and real-world insights, to help you minimize waste, cut costs, and accelerate production.

Whether you’re producing slim-fit styles or relaxed heavy duty denim jeans, understanding denim fabric width impacts everything from cutting precision to final fit. Let’s break it down.

width comparison

Why Denim Fabric Width Matters in Custom Jeans Manufacturing

The denim fabric width directly influences production efficiency in garment factories. Narrower widths, like 140cm (55 inches), allow for precise cuts that reduce fabric waste—studies show optimized widths can improve resource management by 11.4% (MDPI Sustainability Journal). However, wider options up to 190cm (75 inches) are now available on the market for high-volume runs, enabling fewer seams and faster sewing. Yet, for stable shrinkage control, experts recommend sticking to around 140cm (55 inches), as wider fabrics can warp more during washing and drying.

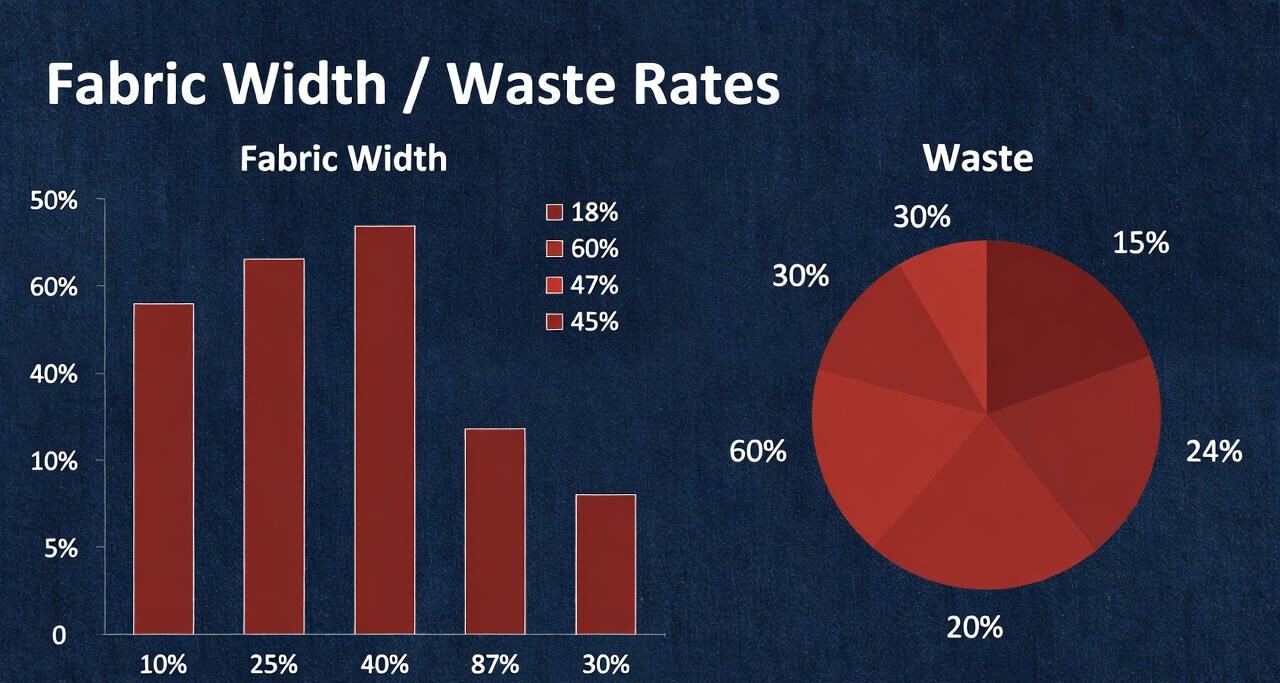

In bulk denim wholesale scenarios, choosing the wrong width can inflate costs by 10-15% due to excess scraps. For made to measure jeans, where every inch counts, the right denim fabric width ensures tailored fits without compromising speed.

- Narrow Widths (e.g., 120-140cm/47-55 inches): Ideal for slim-fit and skinny jeans; minimizes waste but may require more pattern adjustments.

- Standard Widths (150-160cm/59-63 inches): Versatile for most custom runs; balances speed and economy.

- Wide Widths (170-190cm/67-75 inches): Suited for loose-fit or plus-size styles; boosts throughput but demands advanced cutting tech.

Width stable

5 Optimal Denim Fabric Widths to Boost Production Efficiency

To produce high-quality custom jeans quickly, here are five proven denim fabric width recommendations, tailored for garment factories:

- 140cm (55 inches) – The Stability Star: Perfect for heavy duty denim in men’s workwear. It offers minimal shrinkage (under 3% post-wash), making it reliable for bulk production. Factories report 20% faster cutting times compared to narrower options.

- 150cm (59 inches) – Everyday Efficiency: A go-to for stretch denim in women’s made to measure jeans. This width cuts waste by aligning seamlessly with standard patterns, ideal for high-volume orders.

- 160cm (63 inches) – Versatile Powerhouse: Balances cost and speed for mixed runs of slim and relaxed fits. In a case study, Levi’s leverages similar widths to maintain durability in their iconic 501 style, reducing production time by 15%.

- 170cm (67 inches) – Volume Booster: Great for Wrangler-inspired rugged jeans using heavy duty denim. Wider cuts mean fewer pieces per garment, speeding up assembly by up to 25% in automated lines.

- 190cm (75 inches) – Future-Proof Wide: Emerging for oversized or sustainable custom jeans manufacturing, but use cautiously—it’s prone to higher shrinkage variability. Pair it with laser cutters for optimal results.

These widths align with bulk denim wholesale needs, where suppliers offer rolls optimized for quick turnaround.

For premium heavy duty denim options, check out LY Denim’s non-elastic fabrics—customizable widths starting from 140cm (55 inches) for garment factories focused on durability.

Real-World Fashion Cases: How Brands Nail Denim Fabric Width

Fashion giants prove the power of strategic denim fabric width selection. Levi’s, for instance, sticks to 54-60 inch (137-152cm) standards in their production for timeless fits, enabling global scalability while keeping waste low—key to their 150+ year legacy. In a comparative analysis, Wrangler uses wider effective widths (around 60-65 inches/152-165cm) in heavy duty lines for cowboys and laborers, enhancing ruggedness without extra seams. This approach has helped Wrangler dominate workwear, with production efficiency gains of 18% in high-output facilities.

Smaller brands like Everlane are experimenting with 190cm (75 inches) widths for eco-conscious made to measure jeans, reducing material use per pair by 12%. These cases highlight how denim fabric width drives both quality and innovation.

Reducing Waste and Enhancing Sustainability in Bulk Denim Wholesale

In custom jeans manufacturing, waste from mismatched denim fabric width can hit 15-20% of material costs. By opting for 140-160cm (55-63 inches) in bulk denim wholesale, factories can slash this to under 5%, per industry benchmarks. Integrate data-driven tools like CAD software to simulate cuts, ensuring alignment with your equipment.

For sustainable twists, wider widths support zero-waste patterns, but always prioritize shrinkage-stable options like 140cm (55 inches). Explore LY Denim’s sustainable innovations for eco-friendly heavy duty denim rolls that fit these specs.

FAQs: Answering Key Questions on Denim Fabric Width

What is the best denim fabric width for slim-fit custom jeans? For slim-fit styles, 140cm (55 inches) shines—it’s narrow enough for precision but wide enough for quick yields, cutting waste by 11%.

How does denim fabric width impact production speed? Wider widths like 170cm (67 inches) can accelerate sewing by 20-25%, but test for your line to avoid shrinkage issues.

Is 190cm (75 inches) denim fabric width practical for garment factories? Yes for high-volume loose fits, but 140cm (55 inches) remains the most stable for shrinkage, ideal for quality-focused runs.

How can bulk denim wholesale lower costs with optimal widths? Matching widths to patterns saves 10-15% on materials; source from reliable suppliers for custom rolls.

What role does heavy duty denim play in made to measure jeans? It boosts durability—pair 150cm (59 inches) widths with it for efficient, long-lasting custom pieces.

In summary, mastering denim fabric width empowers garment factories to churn out high-quality custom jeans at record speeds. Start with 140cm (55 inches) for reliability, scale to wider options as needed, and watch your efficiency soar. Ready to upgrade? Dive into bulk denim wholesale today.

Mastering Denim Fabric Width with LYDENIM

Want to produce premium custom jeans faster, with less waste and higher profits? LYDENIM helps garment factories and brands optimize every centimeter of fabric through professional width selection and bespoke denim solutions.

✂️ Optimal Fabric Width Recommendations Start with the most reliable and efficient choice: 140cm (55 inches) — perfect for classic 5-pocket jeans and minimal fabric waste. As your production scales or designs evolve, upgrade to 150–160cm (59–63 inches) wider widths to boost cutting efficiency by 15–25%. LYDENIM offers stable stock in all standard and extra-wide denim widths.

🧵 Professional Bespoke Denim Solutions From heavyweight raw selvedge to lightweight stretch and sustainable recycled denim, LYDENIM delivers custom-developed fabrics that match your exact weight, hand-feel, color, and performance requirements.

📏 Bulk Wholesale & Fast Delivery Ready to upgrade your production line? Enjoy competitive wholesale pricing, consistent quality, and reliable lead times when you source directly with LYDENIM.

📩 Get in Touch Have a denim project or need width optimization advice? Contact LYDENIM’s team at malone@lydenim.com to discuss custom fabrics, wider-width developments, or bulk wholesale orders. Visit LYDENIM for more premium denim collections or explore options on Liangyuan Textile on Alibaba.

Boost speed, cut costs, and elevate quality — partner with LYDENIM for your next winning denim collection!