Slasher Dyeing: How Denim Fabric Gets Its Iconic Blue

Estimated reading time: ~3 minutes

Introduction to Denim Fabric and Dyeing

Denim fabric is a wardrobe staple, loved for its durability and timeless blue hue. But have you ever wondered, what is denim fabric and how it gets that signature color? The secret lies in the dyeing process, and one innovative method that revolutionized denim production is slasher dyeing. Introduced in the 1970s, this technique offers a unique way to color denim yarns, making it a popular choice for creating high-quality denim fabric by the yard. In this post, we’ll dive into how slasher dyeing works, its benefits, and why it matters for denim lovers and fabric buyers alike.

Selvage Denim Detail

What Is Slasher Dyeing?

Unlike traditional rope dyeing, where yarns are bundled into ropes before dyeing, slasher dyeing lays out the yarns as a flat “sheet” or “carpet” warped onto a beam. This sheet-like arrangement is the key difference that sets slasher dyeing apart. Once dyed, the yarns are ready to be woven into denim fabric without the extra step of re-beaming, streamlining the process.

This method emerged in the 1970s as a labor-saving alternative to older techniques. By dyeing yarns individually in a sheet, slasher dyeing reduces manual effort and speeds up production—perfect for meeting the demand for denim fabric wholesale or bulk orders.

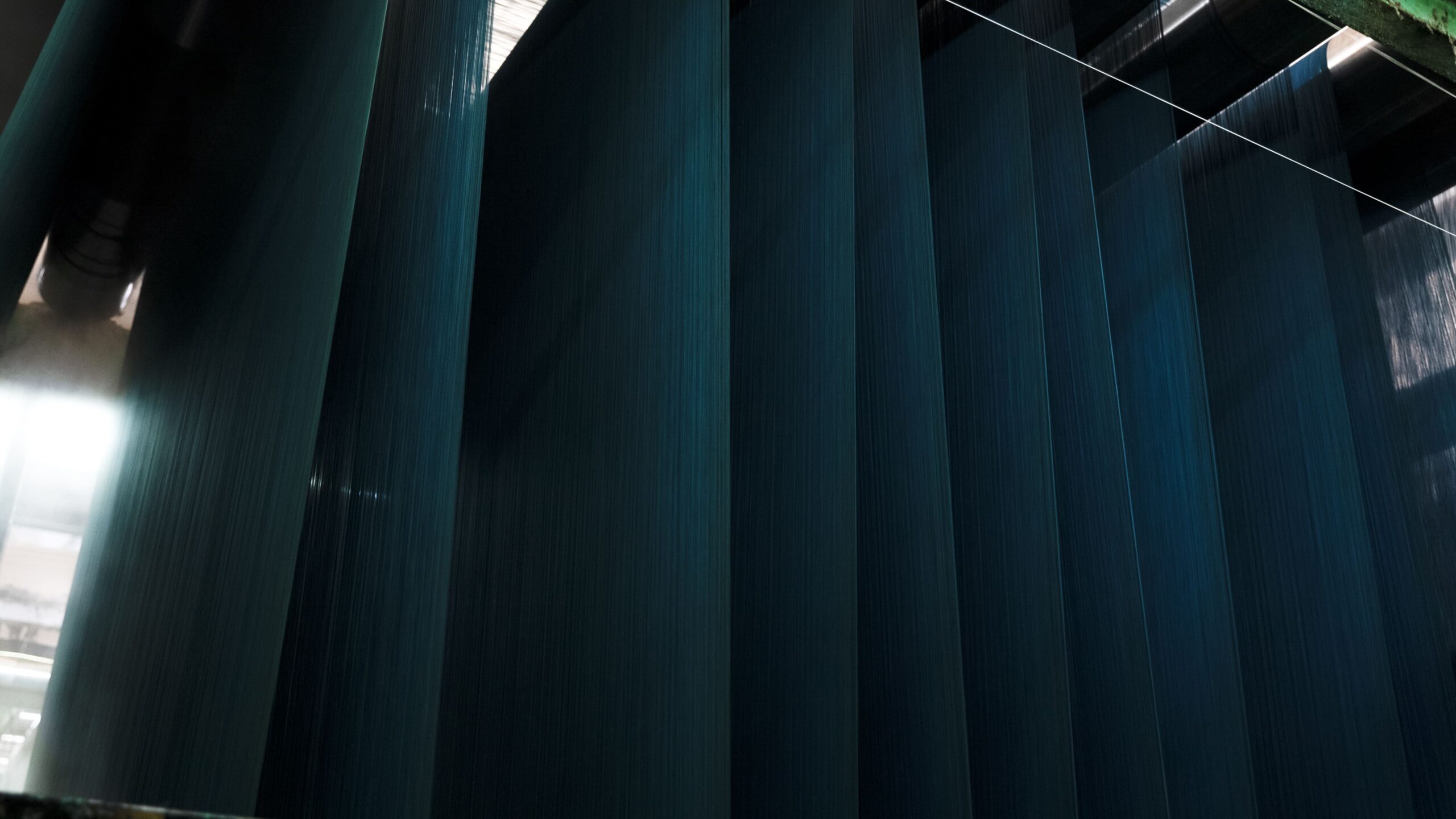

Dyeing

How Is Denim Fabric Made with Slasher Dyeing?

So, how is denim fabric made using this technique? The process starts with warping the yarns onto a beam in a flat arrangement. These yarns then pass through a series of indigo dye baths. Because the yarns are spread out, they only need 10 to 15 seconds of immersion per bath, and oxidation (the process that locks in the blue color) takes just 30 to 60 seconds. This efficiency comes from the greater surface area exposed to air and dye, allowing for faster penetration and color setting.

However, slasher dyeing demands precision. The dye vats must be highly consistent to ensure even coloring across the entire sheet—unlike rope dyeing, which embraces natural inconsistencies for a rugged look. The result? A smooth, uniform denim fabric ideal for everything from jeans to upholstery.

Benefits and Challenges of Slasher Dyeing

Slasher dyeing offers several advantages:

- Efficiency: Less labor and faster dyeing times make it cost-effective for producing denim fabric by the yard.

- Uniformity: The even dye application creates a polished finish, appealing to those seeking consistent quality.

- Versatility: It’s adaptable for various denim weights, from lightweight to heavy denim upholstery fabric.

But there are challenges too. Achieving color consistency across a wide sheet requires advanced equipment and expertise. Unlike rope dyeing’s planned unevenness, slasher dyeing doesn’t naturally produce the faded, vintage look some denim fans crave.

Slasher Dyeing vs. Other Methods

How does slasher dyeing stack up against other techniques? Rope dyeing, for instance, bundles yarns into ropes, creating a textured, uneven dye effect—perfect for raw or selvedge denim. Meanwhile, loop dyeing, a close cousin of slasher dyeing, uses a single dye bath with multiple dips to achieve deeper shades in a smaller space. Each method shapes the final denim fabric differently, catering to varied tastes and uses.

Why Slasher Dyeing Matters for Denim Fabric Buyers

Whether you’re sourcing denim fabric wholesale or shopping for a specific project, understanding slasher dyeing can guide your choice. Its efficiency and uniformity make it a go-to for manufacturers producing affordable, high-volume denim. Plus, the quick process supports sustainability by reducing labor and time, aligning with modern eco-conscious trends.

Curious about what fabric is denim made of? Typically, it’s cotton or a cotton blend, and slasher dyeing enhances its appeal by delivering that iconic blue with precision.

Conclusion

Slasher dyeing may not have the artisanal charm of rope dyeing, but its innovation has shaped the denim world since the 1970s. From denim fabric by the yard to ready-to-wear jeans, this method ensures quality and efficiency.

Customization Services by LYDENIM

🎨 Want custom denim fabrics or unique custom denim garment? LYDENIM specializes in tailor-made solutions to meet your design and production needs.

🛍️ Explore & Get Inspired: Browse our fabric selections and discover design ideas on LYDenim.

🌐 Elastic Clothing: Check out our offerings on MyAlibaba. 📩 Contact Us: Reach out at malone@lydenim.com.

Create your denim masterpiece with LYDENIM—your trusted partner for stretch fabric and custom denim solutions.