Comprehensive Analysis of Cotton Content in Denim: Is Higher Cotton Always Better?

Estimated reading time: ~5 minutes

Understanding Denim Fabric Composition

Traditional denim consists of a cotton-based twill fabric structure that contains 100% cotton fibers in its composition. Levi Strauss developed work pants for gold miners during the mid-19th century which resulted in the creation of denim fabric that maintained its core characteristics. Denim obtains its recognizable diagonal weave through the combination of indigo-dyed warp threads with undyed weft threads which produces both texture and fading potential for achieving the distinctive “worn-in” look from washing methods.

The advancement of textile technology together with market demand changes led to a shift of denim fabric composition from pure cotton to various combinations of different fibers. Modern denim fabric includes cotton as its main material together with additional components such as:

-

Polyester: Enhances durability and resilience

Polyester

-

Elastane (Spandex/Lycra): Adds stretch recovery (typically 1-5%)

Low-Stretch Selvedge

-

Rayon (Viscose): Improves drape and reduces costs

Rayon

-

Recycled Cotton/Polyester: Enhances sustainability

Recycled Cotton

-

Advanced Cellulosics (Tencel, Modal): Improves drape and comfort

Lyocel fabric

These fiber additions have diversified the performance characteristics of traditional denim while maintaining its aesthetic identity. Crucially, the concept of “true denim” has evolved from strict cotton composition to a broader style definition—any fabric maintaining denim’s characteristic twill structure and appearance qualifies as denim, regardless of fiber content.

Characteristics of High-Cotton Denim

High-cotton content denim (typically 95%-100% cotton) preserves classic denim qualities, offering significant advantages alongside notable limitations:

Advantages:

-

Exceptional Breathability and Moisture Absorption: Cotton’s natural hollow fiber structure can absorb up to 24% of its weight in moisture without feeling damp. During summer wear, it effectively wicks sweat and facilitates evaporation, maintaining skin dryness10. This makes pure cotton denim ideal for breathability-focused consumers.

-

Skin-Friendly Comfort and Hypoallergenic Properties: With a smooth surface free from chemical irritants and pH compatibility with human skin, cotton is particularly suitable for sensitive skin and infant clothing. Studies indicate that pure cotton causes approximately 67% less skin irritation compared to synthetic fabrics.

-

Classic Aesthetic Evolution: High-cotton denim develops natural creases and fades that conform to the wearer’s body over time—a distinctive “memory effect” difficult to replicate with synthetic fibers. This characteristic is especially valued by premium denim enthusiasts.

-

Environmental Sustainability: Pure cotton denim is biodegradable at end-of-life. Research shows that under industrial composting conditions, pure cotton denim decomposes over 90% within 77 days, while a 24% polyester blend decomposes only about 40% under the same conditions, leaving synthetic residues

High-Cotton Denim

Limitations:

-

Pronounced Wrinkling and Poor Shape Retention: Cotton’s low elasticity recovery leads to permanent bagging behind knees and at elbows. Test data shows that after 20 wear-wash cycles, knee deformation in pure cotton jeans reaches 12-15%, compared to just 5-8% in polyester-blended counterparts.

-

Significant Shrinkage Issues: Untreated pure cotton denim can shrink 3%-5% during initial washing—an 80cm waistband could reduce by 2-4cm10. Even with modern pre-shrinking treatments (Sanforization), residual shrinkage of 1-2% remains possible.

-

Slow Drying Time: Cotton’s high water absorbency results in drying times approximately twice as long as polyester blends. Under standard conditions (25°C, 65% humidity), pure cotton denim requires 4-6 hours to dry completely, while a cotton-polyester blend (65/35) dries in just 2-3 hours.

-

Moderate Abrasion Resistance: Cotton fibers withstand approximately one-third the abrasion cycles of polyester. Martindale abrasion tests show pure cotton denim exhibits significant wear after 25,000 rubs, while a cotton-polyester blend (50/50) withstands over 50,000 rubs.

Table: Performance Profile of High-Cotton Denim

| Attribute | Advantages | Limitations |

|---|---|---|

| Comfort | Excellent breathability, superior moisture absorption, skin-friendly | Slow drying, heavy when wet |

| Durability | Moderate natural strength | Lower abrasion resistance, prone to tearing |

| Care & Maintenance | Withstands hot ironing, can be sterilized at high temperatures | Prone to wrinkling, significant shrinkage, poor wrinkle recovery |

| Aesthetics | Natural fading patterns, classic texture | Fades and distorts after repeated washing |

| Environment | Biodegradable, relatively eco-friendly production | High water consumption (cultivation phase) |

Screenshot

Is Higher Cotton Always Better? A Balanced Perspective

While high-cotton denim offers notable benefits, considering it “inherently superior” is misleading. Fabric performance must be evaluated holistically based on usage scenarios and personal priorities:

Ideal Applications for High-Cotton Denim:

-

Traditional and Vintage Style Enthusiasts: Seeking authentic fading patterns and heritage textures

-

Individuals with Sensitive Skin: Needing to avoid potential synthetic fiber irritants

-

Warm Climate Everyday Wear: Leveraging superior breathability and moisture management

-

Eco-Conscious Consumers: Prioritizing biodegradability

Problematic Applications for High-Cotton Denim:

-

High-Activity and Travel Contexts: Pure cotton denim deforms during strenuous activities and dries too slowly for travel convenience. During hiking, pure cotton jeans can increase in weight by 20% when sweaty and take twice as long to dry as quick-drying blends.

-

Body-Shaping Requirements: Rigid pure cotton lacks the flexibility to contour body shapes effectively for modern skinny jeans. Blends with 2% elastane provide 15%-20% stretch for better freedom of movement.

-

Low-Maintenance Priorities: Urban professionals may find the ironing requirements burdensome. Surveys indicate 76% of working adults prioritize “wrinkle resistance” in clothing.

-

Budget-Conscious Consumers: Premium cotton (e.g., Egyptian) costs significantly more than blended alternatives. Production costs for Egyptian cotton denim run approximately 40% higher than cotton-polyester blends (70/30), resulting in substantial retail price differences.

Environmental Reconsideration:

Despite being a natural fiber, cotton’s environmental footprint requires critical examination:

-

Producing 1kg of conventional cotton consumes 7,000-29,000 liters of water (depending on region)

-

Cotton cultivation uses 16% of global insecticides and 7% of pesticides

-

Traditional indigo dyeing generates substantial wastewater pollution

Comparatively, incorporating recycled cotton (e.g., 50% recycled + 50% conventional) reduces impacts:

-

Global Warming Potential (GWP) ↓18%

-

Eutrophication (EU) ↓25%

-

Acidification (AC) ↓25%

-

Fossil Resource Scarcity ↓15%

Alternative Blend Formulations and Properties

Modern denim utilizes strategic fiber blending for performance optimization. Key blend types include:

1. Cotton + Polyester (Common ratios: 65%-80% cotton + 20%-35% polyester)

-

Advantages: Enhanced abrasion resistance and wrinkle recovery; minimized shrinkage (<2%); faster drying (30-50% reduction); 20-30% cost reduction

-

Limitations: Reduced breathability; synthetic hand feel; static buildup

-

Best For: Fast fashion, everyday workwear, student apparel

2. Cotton + Lyocell (Common ratios: 70%-85% cotton + 15%-30% lyocell)

-

Advantages: Combines cotton’s breathability with lyocell’s silky drape; enhanced moisture management (30% better than cotton); improved biodegradability; reduced pilling

-

Limitations: Lower wet strength requiring gentle care; higher cost (lyocell ≈25% pricier than cotton)

-

Best For: Premium women’s jeans, lightweight summer styles, sustainable brands

Premium women’s jeans

3. Cotton + Elastane (Common ratios: 92%-98% cotton + 2%-8% elastane)

-

Advantages: Provides comfort stretch (15%-25% elongation); maintains natural cotton feel; enhances body contouring

-

Limitations: Knee bagging after extended wear; chlorine sensitivity; recycling complications

-

Best For: Skinny jeans, athleisure styles, comfort-focused consumers

Skinny jeans

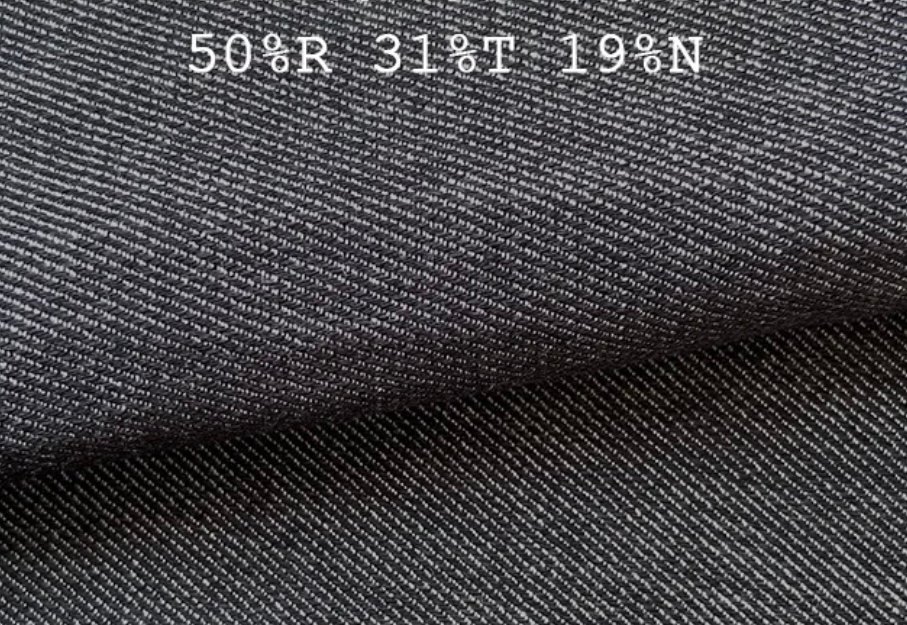

4. Recycled Blends (Recycled Cotton + Recycled Polyester)

-

Advantages: Reduces water consumption (>80% vs. virgin cotton); lowers carbon footprint (40%-60% reduction vs. conventional)

-

Limitations: Shorter fibers reduce strength; limited color options; higher costs

-

Best For: Eco-conscious brands, ESG-focused product lines

Table: Performance Comparison of Common Denim Blends

| Performance Attribute | 100% Cotton | Cotton-Poly (70/30) | Cotton-Tencel (80/20) | Cotton-Elastane (95/5) |

|---|---|---|---|---|

| Breathability | ⭐⭐⭐⭐⭐ | ⭐⭐☆ | ⭐⭐⭐⭐ | ⭐⭐⭐⭐ |

| Abrasion Resistance | ⭐⭐☆ | ⭐⭐⭐⭐⭐ | ⭐⭐⭐ | ⭐⭐☆ |

| Wrinkle Recovery | ⭐☆ | ⭐⭐⭐⭐ | ⭐⭐⭐ | ⭐⭐⭐ |

| Stretch Recovery | ⭐☆ | ⭐⭐☆ | ⭐⭐☆ | ⭐⭐⭐⭐⭐ |

| Drying Speed | ⭐⭐☆ | ⭐⭐⭐⭐⭐ | ⭐⭐⭐ | ⭐⭐☆ |

| Eco-Friendliness | ⭐⭐⭐⭐ | ⭐☆ | ⭐⭐⭐⭐ | ⭐⭐☆ |

| Cost Efficiency | High | Low | High | Medium-High |

Research and Data Insights

Academic and Industry Findings

-

Compostability Study (2024)

Cornell University research on denim decomposition revealed:-

Pure cotton denim degraded >90% in 77 days under industrial composting

-

Denim with 24% polyester + 2% elastane degraded ≈60%, leaving synthetic residues

-

Natural dyes (e.g., madder, indigo) didn’t inhibit decomposition

-

-

Life Cycle Assessment (Journal of Cleaner Production, 2024)

Comparative analysis of denim manufacturing impacts showed:-

Replacing 50% virgin cotton with recycled cotton while using renewable energy (hydropower) reduced:

-

Global Warming Potential (GWP): ↓18%

-

Eutrophication (EU): ↓25%

-

Acidification (AC): ↓25%

-

Fossil Resource Scarcity: ↓15%

-

-

Solar and hydropower delivered the most significant carbon footprint reductions

-

-

Sustainable Dyeing Research (2021)

Optimized indigo dyeing through green chemistry alternatives achieved:-

62.5% reduction in conventional chemicals

-

≈35% water consumption reduction

-

Maintained color fastness while improving environmental metrics

-

Consumer Preferences and Market Data

-

Comfort Priority: Global consumer surveys indicate 65% of buyers rank “wearing comfort” as their primary concern, surpassing “durability” (20%) and “appearance” (15%)

-

Stretch Demand Growth: Between 2018-2023, stretch-denim market share grew from 45% to 68%, reflecting consumer preference for elasticity

-

Price Sensitivity: In value markets, cotton-polyester blends (65/35) dominate ≈60% market share due to 25%-30% lower prices versus pure cotton

Industry Expert Perspective

“Denim selection should balance performance with responsibility. While cotton offers natural advantages, ignoring advances in blend technology and recycled materials hinders sustainable progress. Future leaders will be products that artfully combine cotton’s comfort with technical fibers’ functionality and recycled materials’ eco-benefits.”

— Textile Sustainability Research Center, 2024 Annual Report9

Informed Decision-Making Framework

The ideal cotton content in denim depends on usage context, personal preferences, and sustainability values rather than absolute percentages:

-

When Choosing High-Cotton (95%-100%): You gain optimal breathability, authentic aesthetics, and biodegradability, but must accept maintenance requirements (ironing, careful washing), slow drying, and potential shrinkage/distortion.

-

When Opting for Mid-Range Cotton Blends (70%-90%):

-

Cotton-Polyester: Boosts durability and quick-drying for active lifestyles but reduces breathability and natural feel

-

Cotton-Lyocell: Balances comfort with elegant drape, enhancing moisture management for premium casualwear

-

Cotton-Elastane: Delivers essential stretch for mobility but complicates recycling

-

-

For Eco-Prioritized Selection: Consider recycled content (certified by GRS) and brands implementing water stewardship and advanced dyeing technologies (e.g., ozone, laser). Research confirms that combining recycled materials with renewable energy can reduce denim’s comprehensive environmental footprint by over 35%.

Table: Denim Selection Guide by Usage Scenario

| Usage Scenario & Needs | Recommended Blend | Key Benefits | Considerations |

|---|---|---|---|

| Authentic Vintage Style | 100% Cotton | Natural fading, heritage authenticity | Expect shrinkage and bagging |

| Outdoor/Travel | Cotton 78% + Polyester 22% | Quick-drying, abrasion-resistant, wrinkle-resistant | Reduced breathability |

| Body-Shaping Fit | Cotton 92% + Elastane 8% | High stretch, body contouring | Avoid chlorine bleach, knee bagging |

| Premium Comfort | Cotton 85% + Lyocell 15% | Silky drape, superior moisture management | Gentle wet care, premium price |

| Eco-Conscious Choice | Recycled Cotton 50% + Recycled Polyester 50% | Low carbon, water conservation | Limited colors, higher cost |

Decision Checklist:

-

Comfort Priority: Sensitive skin or breathability focus → Choose high-cotton (>80%) or cotton-lyocell

-

Activity Level: Frequent wear or high movement → Select cotton-polyester blends (≥20% polyester)

-

Fit Requirements: Skinny/slim silhouettes → Ensure elastane content (3%-8%)

-

Easy Care: Wrinkle resistance → Opt for ≥30% polyester blends

-

Eco-Values: Prioritize recycled content (GRS-certified) and clean dyeing technologies

-

Budget Balance: Weigh initial cost against longevity—quality blends may outperform cheap pure cotton

Denim selection is fundamentally a science of balanced trade-offs. Pure cotton represents tradition and natural beauty, while modern blends provide solutions for diverse contemporary needs. As sustainable fashion gains urgency, informed consumers should move beyond “cotton supremacy” to make evidence-based choices that align with personal requirements and environmental responsibility—ultimately driving the industry toward more sustainable practices.

Customization Services by LYDENIM

Looking for high-cotton-content denim or custom-blend fabrics with unique textures? LYDENIM offers tailor-made solutions to meet your design and production needs.

-

🎨 Custom Fabrics: Discover high-cotton denim or specialized blends (e.g., cotton-spandex or cotton-polyester) with diverse textures on LYDENIM.

-

🛍️ Textured Clothing: Explore our range of custom denim garments with varied weaves and blends on Myalibaba.

-

📩 Contact Us: Reach out at malone@lydenim.com to discuss your fabric or apparel requirements.

Create your denim masterpiece with LYDENIM—your trusted partner for high-quality, custom-textured fabrics and innovative denim apparel.