Spandex in Denim: Revolutionizing Comfort and Style

Estimated reading time: ~5 minutes

Introduction

The fundamental fabric of jeans which started as durable work clothing has evolved into multiple fashion uses. The evolution of denim into a fashion staple is primarily attributed to spandex because this synthetic material possesses superior elasticity. Stretch denim emerges from the combination of denim with Lycra or elastane or stretch which merges the strength of denim with comfort features. This paper examines the history of spandex development alongside its textile integration and assesses its industrial advantages and constraints and explores its effects on denim manufacturing and the textile industry.

Chemical spandex

What is Spandex? Origins and Names

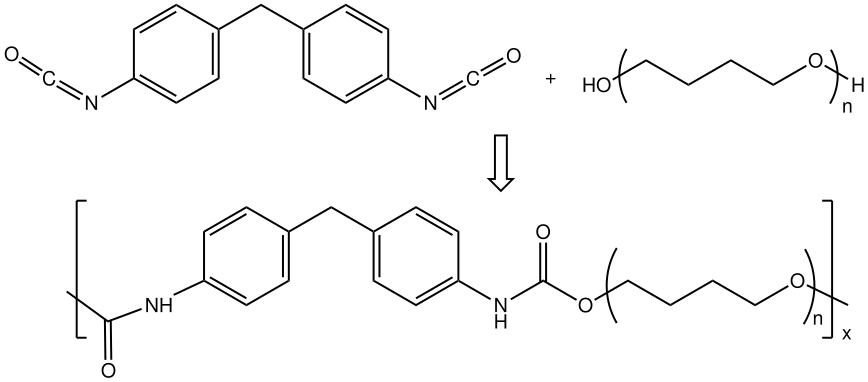

The synthetic material known as spandex or Lycra or elastane or stretch stretches 500–800% of its initial length before returning to its original form. The polyether-polyurea copolymer composition of this material includes at least 85% polyurethane which results from the reaction between polyester or polyether and a diisocyanate compound. The laboratory production of spandex differs from cotton because it derives from petroleum-based synthetic materials.

The research at IG Farben in Germany led to the development of polyurethane materials in the 1930s. DuPont obtained the research after World War II before Joseph Shivers at DuPont’s Benger Laboratory in Virginia created spandex in 1959. The material received its first name as “Fiber K” before DuPont introduced it to the market as Lycra in 1962. Spandex serves as an anagram of “expands” to describe its elastic properties and is mainly used in North America although Europe prefers the term elastane. The Lycra Company which was formerly known as DuPont holds the trademark rights to Lycra.

lycra

Weaving Spandex into Denim: Elasticity in Action

Denim fabric originates from the twill weaving method which uses cotton yarns to create diagonal patterns in warp and weft directions. The introduction of spandex to denim fabric provides stretchiness along with form-fitting properties. The stretch denim manufacturing process includes 2–4% spandex but specialized items such as jeggings can have up to 20% spandex content.

How Spandex is Incorporated

- Weaving Process: Spandex is blended with cotton, usually in the weft yarn, to create stretch denim. Core-spun yarns, where spandex is encased in cotton fibers, are common, enabling weft stretch (one-way) or four-way stretch (both warp and weft). Four-way stretch denim, with spandex in both yarn types, offers maximum flexibility for activewear or fitted jeans.

- Stretch Mechanism: Spandex fibers consist of soft, amorphous segments and rigid segments. When stretched, the amorphous segments elongate, and upon release, they recoil, providing a snug yet comfortable fit. For example, jeans with 2–4% spandex can stretch 20–30% of their original size, enhancing mobility while retaining denim’s durability.

Four-Way Stretch Fabric

Impact on Denim

The incorporation of spandex in denim production creates stretchy fabric that adapts to contemporary fashion trends and comfort requirements. Stretch denim shapes itself to body curves which produces appealing silhouettes for jeans and dresses and skirts while maintaining the classic denim aesthetic. The development of stretch jeans has become popular among young people because these stretchable pants unite fashion with comfort during physical activities.

Pros and Cons of Spandex in Denim

Spandex enhances denim’s functionality but comes with trade-offs. Here’s a balanced analysis:

Advantages

- Comfort: The stretchy nature of spandex allows denim to fit closely to the body while providing comfort for long periods of wear particularly for tight jeans and activewear.

- Shape Retention:The elastic nature of the material maintains the garment shape through its ability to resist bagging.

- Versatility: Stretch denim provides versatility because it works well for both casual jeans and athleisure and shapewear items.

- Durability: Spandex exhibits durability through its resistance to abrasion and body oils and sweat and detergents when properly cared for.

- Aesthetic Appeal: Stretch denim fabric allows for better dyeability which leads to vibrant and enduring color results.

strech cloth

Disadvantages

- Durability Issues: Higher percentages of spandex exceeding 10% in a fabric may cause structural damage that results in sagging unless proper maintenance is performed.

- Heat Sensitivity: High temperatures in washing and drying processes and manufacturing operations cause spandex to lose its elasticity thus reducing performance quality.

- Breathability: High-spandex blends may trap heat, though cotton blends improve comfort.

- Environmental Impact: Spandex which originates from petroleum represents a non-biodegradable fiber with production processes that generate up to 9 kg of CO₂ per kilogram according to the Textile Exchange (2023).

- Care Complexity: The care requirements for Spandex include washing in cold water and avoiding bleach usage while requiring air drying to maintain elasticity.

Spandex Yarn

Spandex in Denim Manufacturing: Temperature Considerations

Spandex’s heat sensitivity affects its performance in denim manufacturing processes like singeing, laminating, flocking, and printing. Below are the typical temperatures and their impact:

- Singeing: Burns off surface fuzz at 800–1000°C for milliseconds. Spandex’s melting point is 175–178°C, but elasticity degrades above 120–150°C. Brief exposure minimizes damage, but prolonged heat can reduce stretch by 10–20%. Low-spandex blends (2–4%) are less affected.

- Laminating: Bonds denim to materials like waterproof layers at 150–200°C. Extended exposure above 150°C can weaken spandex, reducing elasticity by up to 30%. Precise temperature control is essential.

- Flocking: Applies fibers for a velvet-like texture, with adhesives cured at 120–160°C. Prolonged exposure above 150°C may reduce elasticity by 15–25%. Low-temperature adhesives are preferred.

- Printing: Heat-sets dyes at 130–180°C. Temperatures above 150°C can reduce spandex stretch by 10–20%, especially in high-spandex blends. Low-temperature inks help preserve elasticity.

General Impact: Spandex in denim (2–4%) begins losing elasticity at 120–150°C, with significant degradation above 150°C for extended periods. Brief high-temperature processes like singeing have minimal impact, but laminating and flocking require careful temperature management to maintain stretch.

Industry Insights and Research

Spandex’s role in denim is backed by market data and expert perspectives:

-

Market Data: The global denim jeans market, valued at $86.66 billion in 2024, is projected to reach $121.50 billion by 2030 (CAGR 5.9%, Grand View Research, 2024). Stretch denim, driven by spandex, accounts for 70% of U.S. jeans sales (Cotton Incorporated, 2023).

-

Expert Quote: “Spandex has redefined denim’s role in fashion, making jeans not just durable but wearable all day with unmatched comfort.” – Textile expert, Fibre2Fashion, 2013.

-

Blog Insight: “Spandex’s ability to stretch up to 500% while retaining shape has made stretch jeans a wardrobe staple, especially for younger consumers.” – Cotton Monk, 2024.

-

Sustainability Concerns: Spandex production emits 9 kg of CO₂ per kg, but innovations like The Lycra Company’s bio-based Lycra reduce emissions by up to 30% (Fibre2Fashion, 2025).

-

Consumer Trends: A 2023 Zeva Denim survey found 65% of consumers prefer stretch denim for comfort, with 80% of women’s jeans containing 2–4% spandex.

These insights highlight spandex’s transformative impact and the push for sustainable alternatives.

Conclusion

Spandex has ushered in a “stretch revolution” for denim, making jeans comfortable, form-fitting, and versatile. Its ability to stretch 500–800% while retaining shape has made stretch denim a favorite for jeans, skirts, and activewear. However, its heat sensitivity and environmental footprint require careful manufacturing and care. With the denim market projected to reach $121.50 billion by 2030, spandex will continue driving innovation, with eco-friendly alternatives like bio-based spandex addressing sustainability concerns. Spandex ensures denim remains a stylish, functional cornerstone of modern fashion.

Customization Services by LYDENIM

🎨 Looking for custom stretch denim fabric or stretch apparel?

LYDENIM specializes in tailor-made solutions to meet your design and production needs.

🛍️ Explore & Get Inspired:

Browse our fabric selections and discover design ideas directly on LYDENIM

🌐 Elastic clothing: Myalibaba

📩 Contact Us:malone@lydenim.com

Create your denim masterpiece with LYDENIM — your trusted partner for stretch fabric and custom denim solutions.