Are You Looking for Stretch Denim Fabric or Stretch Denim Garments?

Estimated reading time: ~4 minutes

The Growing Demand for Stretch Denim

The rise of casual and comfortable fashion has transformed consumer preferences, with stretch denim leading the charge. Fueled by post-pandemic shifts toward hybrid work and relaxed lifestyles, consumers crave jeans that blend style with flexibility. Industry reports highlight a surge in demand for comfortable, form-fitting denim, making stretch denim a top choice for brands and manufacturers aiming to capture this trend.

Why Choose Spandex Stretch Denim?

Spandex (also known as Lycra®, elastane, or stretch) is a high-elasticity synthetic fiber that revolutionizes denim’s performance when blended into the fabric. Here’s why it stands out:

lycra

- Superior Stretch and Recovery: Spandex can stretch 5–8 times its original length and snap back, offering a snug, comfortable fit that moves with the wearer, ideal for daily activities or dynamic motion.

- Lightweight and Soft: Spandex fibers are fine and soft, ensuring stretch denim remains lightweight without sacrificing comfort, perfect for tailored, form-fitting designs.

- Durability: Spandex enhances denim’s resistance to abrasion and tearing, maintaining shape even after repeated stretching or washing, extending garment life.

- Breathability: When blended with cotton, stretch denim retains excellent breathability, wicking moisture to keep wearers cool and comfortable compared to rigid denim.

Compatibility with Manufacturing Processes

Stretch denim adapts seamlessly to various finishing processes, enabling diverse design possibilities. However, careful temperature control is crucial to preserve spandex’s elasticity:

- Printing: Stretch denim supports reactive or disperse printing for vibrant patterns. Keep drying and curing temperatures below 60–80°C and setting temperatures below 180°C to avoid damaging spandex fibers.

- Laminating: Bonding denim with materials like waterproof films requires low-melt adhesives and temperatures below 180°C to prevent elasticity loss or fabric distortion.

Bonding

- Flocking: Applying fibers for a velvet-like texture involves curing adhesives at 120–160°C. Use low-temperature adhesives to maintain spandex’s stretch, avoiding prolonged exposure above 150°C.

Key Tip: For washing, keep water temperatures below 40°C and drying at 60–80°C. Setting ovens should not exceed 180°C to prevent spandex degradation, ensuring long-lasting elasticity.

Versatile Applications in Fashion

Stretch denim’s unique properties make it ideal for a wide range of garments, catering to diverse market needs:

- Skinny Jeans and Leggings: Stretch denim hugs the body, offering freedom of movement without sacrificing shape, perfect for slim-fit jeans or denim leggings.

monjeans vs skinny jeans

- Casual Activewear: Joggers and moto pants combine denim’s rugged aesthetic with stretch comfort, ideal for active lifestyles or prolonged sitting.

Outfits Casuales

- Jackets and Shirts: Stretch denim jackets and shirts provide flexibility while retaining classic denim style, suitable for varied seasons and settings.

Denim Jackets

- Women’s Fashion: From body-hugging skirts to shorts and A-line dresses, stretch denim enhances fit and comfort, delivering chic, tailored looks.

Vaqueros Holgados y Acampanados

From fitted to relaxed styles, stretch denim empowers brands to innovate across casual and formal designs, meeting diverse consumer preferences.

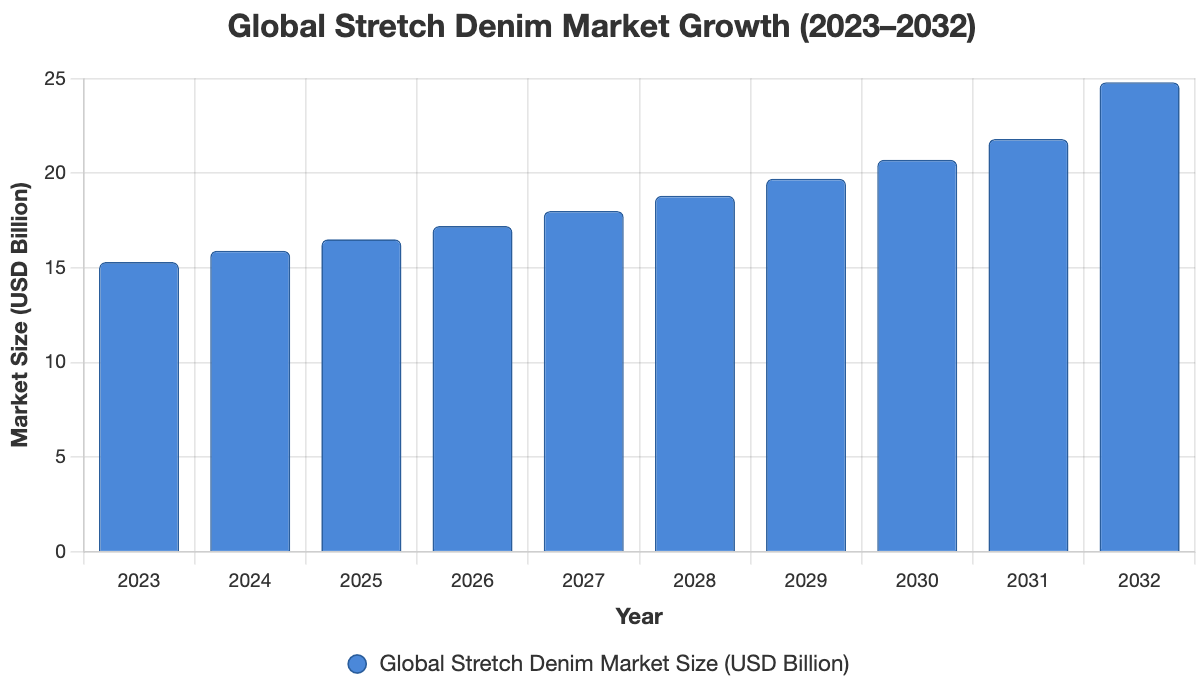

Market Outlook

The stretch denim market is booming. Valued at $15.3 billion in 2023, it’s projected to reach $24.8 billion by 2032, with a CAGR of 5.6% (Allied Market Research, 2023). The Asia-Pacific region, led by China, India, and Bangladesh, drives this growth, fueled by rising consumer spending and robust textile industries. Four-way stretch denim is a rising star, appealing to younger consumers seeking athleisure-inspired fashion. This trend encourages brands to prioritize stretch denim for product innovation, ensuring competitiveness in a dynamic market.

Procurement Tips for Buyers

To source high-quality stretch denim, fabric buyers and manufacturers should consider:

- Spandex Content: Check labels for spandex content, typically 2–5% for standard stretch denim. Higher content (e.g., 10%) suits ultra-elastic designs but verify accuracy to ensure fit and comfort.

- Heat Resistance: Opt for fabrics tested for heat-setting stability (e.g., 200°C+). This ensures durability during dyeing, finishing, and ironing without compromising elasticity.

- Colorfastness: Choose fabrics with high dye fastness, treated with fixing agents to prevent fading or bleeding, ensuring vibrant, long-lasting colors.

- Certifications and Stability: Select suppliers with certifications like OEKO-TEX or REACH, ensuring compliance and consistent quality. Verify chlorine resistance and shape retention for reliable performance.

Partner with reputable suppliers offering clear specifications and batch consistency to minimize risks and deliver premium stretch denim products.

Conclusion

Stretch denim, powered by spandex, is reshaping the fashion industry with its unmatched comfort, durability, and versatility. As the market grows toward $24.8 billion by 2032, brands and manufacturers have a prime opportunity to leverage stretch denim for innovative, consumer-driven designs. By selecting high-quality fabrics and optimizing manufacturing processes, you can create garments that captivate consumers and elevate your brand. Ready to explore stretch denim’s potential? Connect with trusted suppliers today to stay ahead in this thriving market.

Customization Services by LYDENIM

🎨 Looking for custom stretch denim fabric or stretch apparel?

LYDENIM specializes in tailor-made solutions to meet your design and production needs.

🛍️ Explore & Get Inspired:

Browse our fabric selections and discover design ideas directly on LYDENIM

🌐 Elastic clothing: Myalibaba

📩 Contact Us:malone@lydenim.com

Create your denim masterpiece with LYDENIM — your trusted partner for stretch fabric and custom denim solutions.