Understanding Denim Fabric Surface Textures: Weave Structures Decoded

Estimated Reading Time: ~4 minutes

Introduction

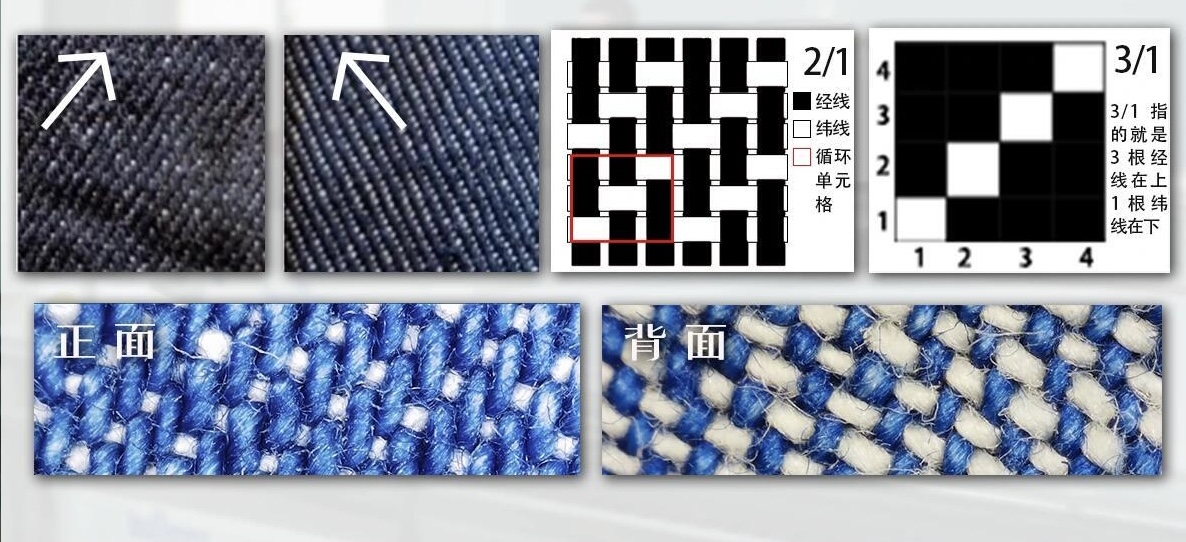

Denim gets its unique look from its weaving process that determines its yarn patterns and density and arrangement. Denim fabric is produced by using 3/1 right-hand twill with coarse cotton yarns and warp yarns receive indigo dye while weft yarns remain undyed to produce diagonal blue-white stripes. The fabric design created through warp floats crossing over weft yarns produces the texture which combines durability with beauty while functioning properly. The paper examines denim weave types along with their technical aspects as well as their advantages and disadvantages and industry knowledge to understand their effects on fabric performance and design.

Loom

What is Denim Surface Texture?

Denim surface texture emerges from how warp (vertical) and weft (horizontal) yarns interlace with each other to create a visible pattern. The diagonal ribs (wales) develop from the twill weave because warp yarns cross multiple weft yarns. The 3/1 twill weave design allows warp yarns to pass over three weft yarns before moving under one weft which generates a distinct diagonal texture. The fabric weight and appearance together with strength are affected by the weave structure as well as yarn count and density while the indigo-dyed warp yarns produce the classic denim appearance.

Twill Weave

Common Denim Weave Structures

Denim weaves get classified through harness count and piece number which describes both the weave pattern and number of harnesses needed (e.g. 3/1, 4/1). The industry standard includes 3-harness, 4-harness, 6-harness, and higher weaves as well as satin weaves. The following section details their technical specifications:

- 3-Harness Twill (2/1): Each warp yarn floats over two wefts and under one, using three harnesses. Produces a fine, tight diagonal pattern, ideal for lightweight denim.

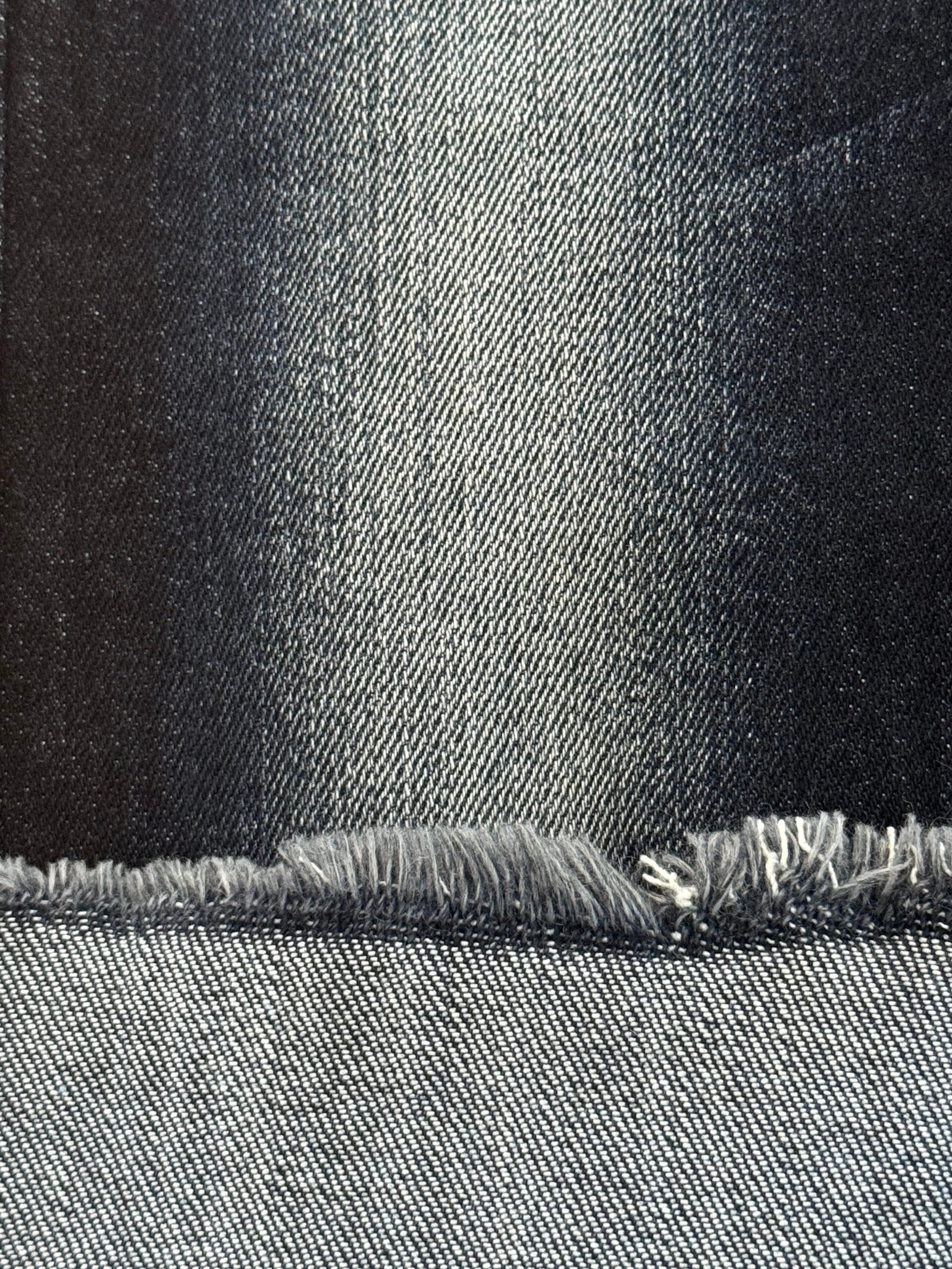

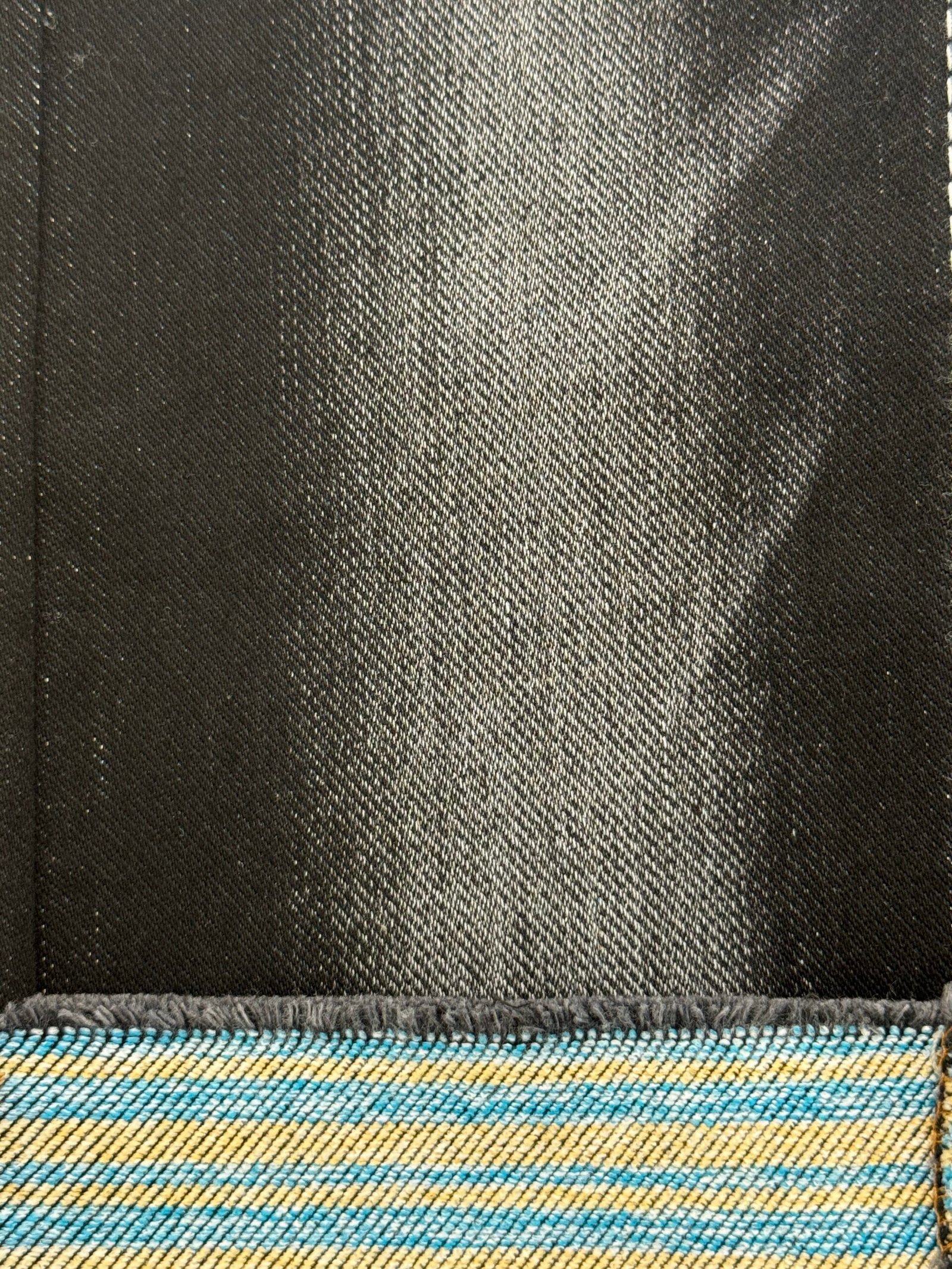

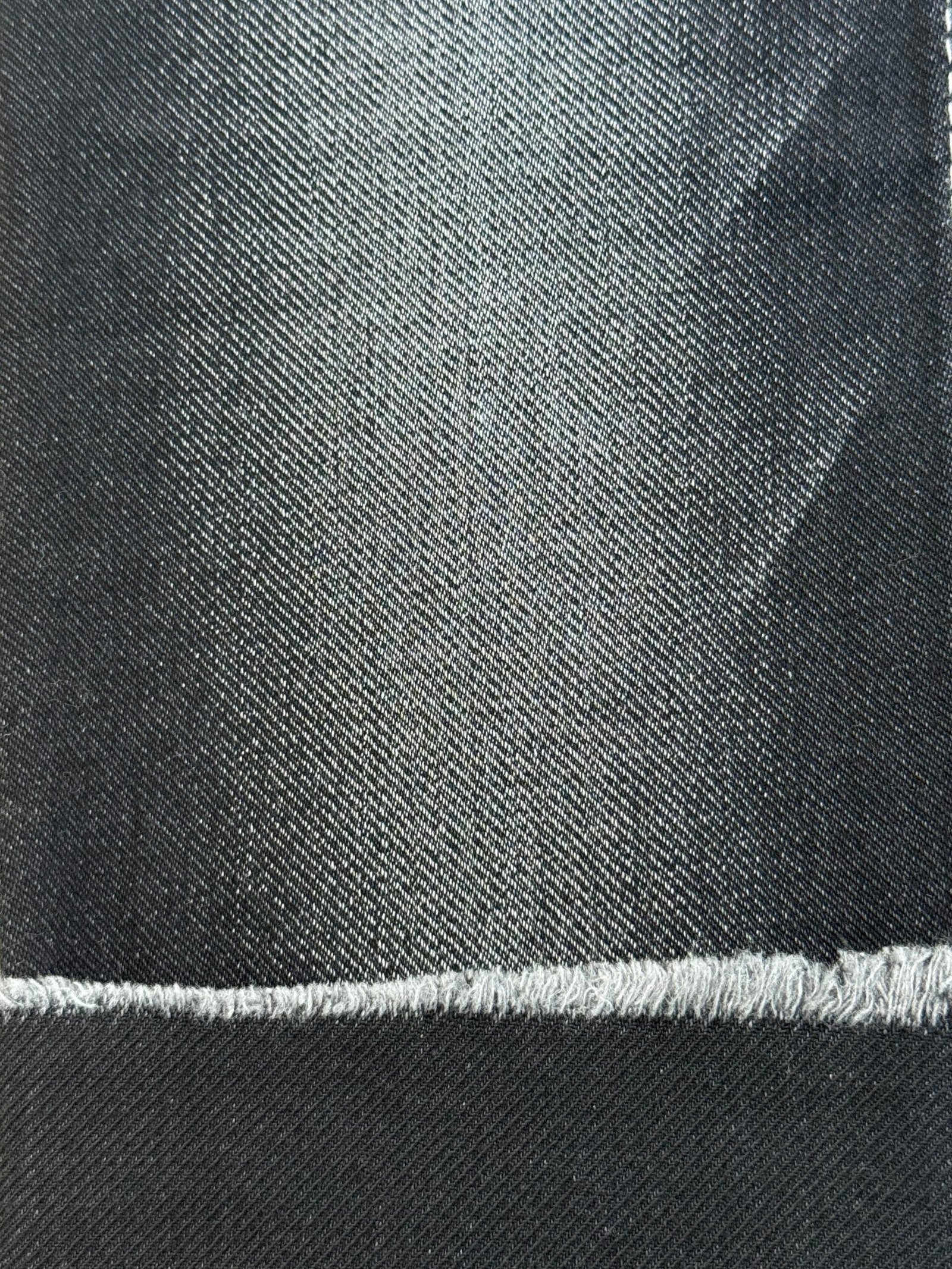

- 4-Harness Twill (3/1): Each warp yarn floats over three wefts and under one, using four harnesses. The most common denim weave, it offers a strong diagonal rib and high tear strength, suited for heavy denim.

4-Harness

- 5-Harness Twill (4/1): Warp floats over four wefts, creating a heavier fabric with a clearer but gentler diagonal pattern.

5-Harness

- 6-Harness Twill (5/1): Warp floats over five wefts, resulting in a flatter diagonal and heavier fabric.

6-Harness

- 8-Harness Twill (7/1): Warp floats over seven wefts, producing a subtle diagonal and very heavy fabric.

8-Harness

- 10-Harness Twill (9/1): Warp floats over nine wefts, creating an extremely sturdy, heavy fabric with minimal diagonal texture.

10-Harness

- 12-Harness Twill (11/1): Warp floats over eleven wefts, yielding the heaviest denim with nearly invisible diagonals.

- Satin Weave (e.g., 5-Harness or 8-Harness): Unlike twill, satin weaves minimize interlacements, with warp yarns floating over four or more wefts (e.g., 4/1 or 7/1). This creates a smooth, glossy surface with excellent drape, often used in “denim satin” or luxury blends.

Satin Weave

Diagram Example: A 3/1 twill fabric pattern demonstrates warp yarns crossing three weft yarns to create extended float lengths and a strong diagonal wale.

Pros and Cons of Denim Weave Structures

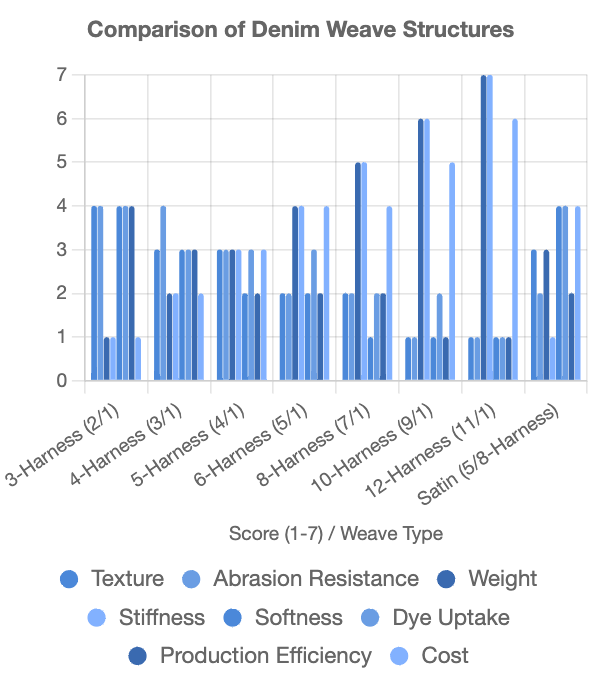

Each weave impacts denim’s appearance, durability, and suitability. Below is a comparative analysis:

| Property | 3-Harness (2/1) | 4-Harness (3/1) | 5-Harness (4/1) | 6-Harness (5/1) | 8-Harness (7/1) | 10-Harness (9/1) | 12-Harness (11/1) | Satin (5/8-Harness) |

|---|---|---|---|---|---|---|---|---|

| Texture | Pronounced diagonal | Strong diagonal | Clear diagonal | Gentler diagonal | Subtle diagonal | Very subtle | Almost flat | Smooth, lustrous |

| Abrasion Resistance | High | High | Medium | Lower | Low | Lowest | Very low | Low (prone to snagging) |

| Weight | Light | Heavy | Heavier | Even heavier | Very heavy | Extra heavy | Extremely heavy | Varies (light to heavy) |

| Stiffness | Soft | Medium | Semi-rigid | Stiffer | Stiff | Very stiff | Hard and thick | Soft, excellent drape |

| Softness | Soft | Moderate | Fairly stiff | Stiffer | Hard | Very hard | Extremely hard | Very soft |

| Dye Uptake | Deep indigo | Deep blue | Deep blue | Moderately deep | Medium blue | Lighter blue | Light blue | Glossy blue |

| Production Efficiency | High (fewer harnesses) | Medium | Lower | Low | Low | Very low | Lowest | Low (complex looms) |

| Cost | Low | Moderate | Higher | High | High | Very high | Highest | High |

Key Insights

- Texture: Shorter floats (2/1, 3/1) create sharp diagonal patterns; longer floats (5/1, 7/1, 11/1) produce flatter, heavier textures. Satin weaves yield a smooth, glossy surface with no visible diagonals.

- Abrasion Resistance: Shorter floats increase interlacements, enhancing durability (e.g., 3/1 twill). Longer floats (7/1, 11/1) or satin weaves reduce interlacements, lowering abrasion resistance (Textile Research Journal, 2020).

- Weight and Stiffness: Longer floats result in heavier, stiffer fabrics. 3/1 and 2/1 are lighter and softer; 7/1 and above are rigid and heavy. Satin weaves are softer with superior drape.

- Dye Uptake: Shorter floats yield saturated indigo hues; longer floats create deeper but less contrasted blues. Satin weaves produce glossy, vibrant colors due to smooth surfaces (Fibre2Fashion, 2023).

- Cost and Efficiency: Weaves with shorter floats (e.g., 3/1) require fewer harnesses (4), reducing costs. Long-float weaves (e.g., 11/1) or satin require 12–16 harnesses, increasing complexity and cost.

Pros and Cons of Denim Weave Structures

Industry Insights

Research and industry data underscore the impact of weave structures:

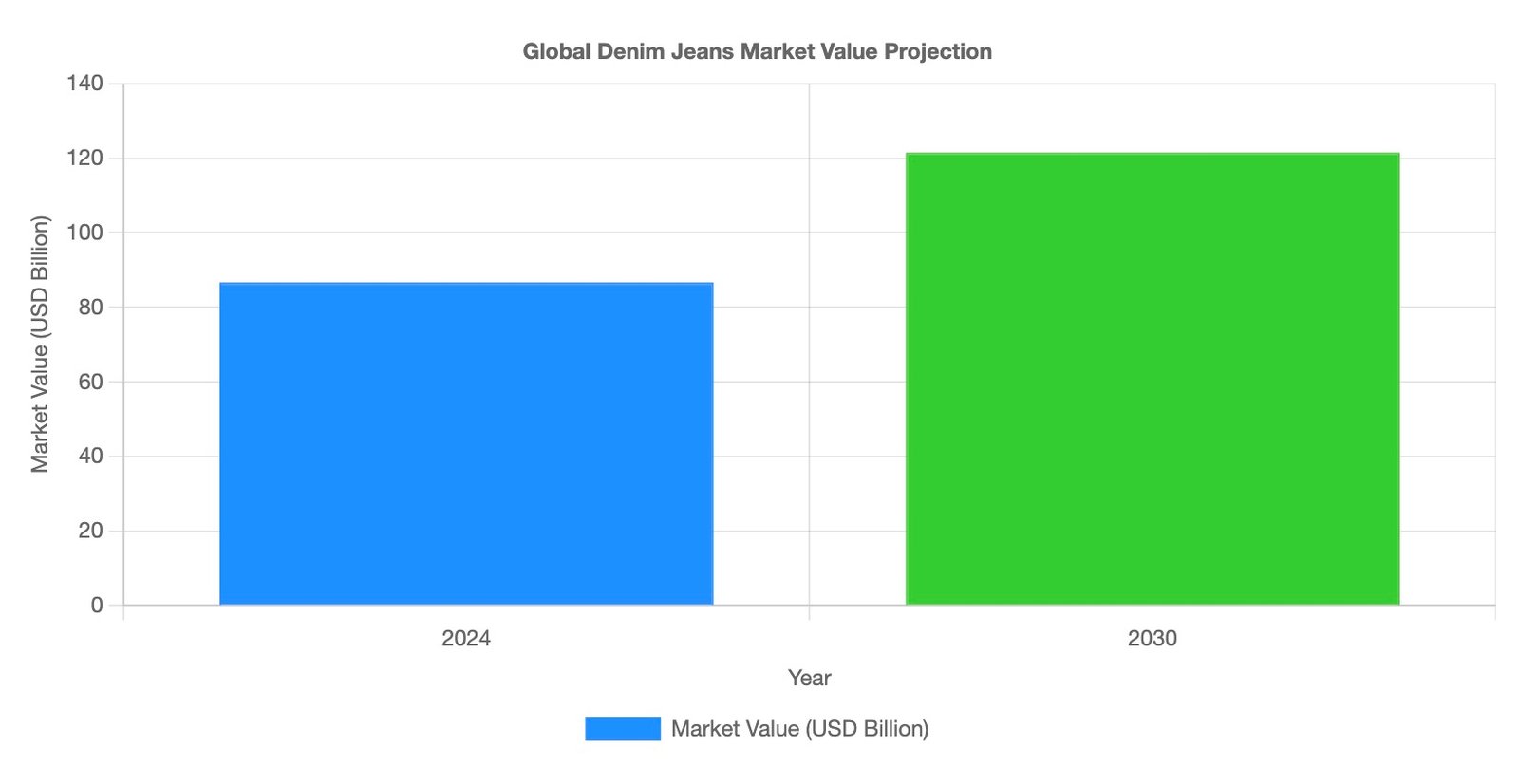

- Market Data: The global denim market, valued at $86.66 billion in 2024, is projected to reach $121.50 billion by 2030 (CAGR 5.9%, Grand View Research, 2024). Weave diversity drives innovation in premium denim.

- Expert Quote: “The choice of twill weave directly influences denim’s durability and aesthetic. A 3/1 twill balances strength and style, while satin weaves elevate luxury.” – Textile engineer, Cotton Incorporated, 2022.

- Blog Insight: “Long-float weaves like 7/1 or satin are gaining traction in high-end denim for their unique texture and drape, despite higher costs.” – Denim Dudes, 2024.

- Technical Study: A 2021 study in the Journal of Textile Science found that 3/1 twill denim has 20% higher tear strength than 7/1 twill due to more interlacements.

Global Denim Jeans Market Value Projection

Conclusion

The structural patterns in denim material determine both functional characteristics and visual appearance. Twills with short floats (2/1 and 3/1) create strong diagonal lines and durable fabric that suits traditional jeans construction. The creation of premium or rugged applications depends on the use of twill structures with longer float lengths (7/1 and 11/1). The satin weaving method produces a luxurious glossy finish and great drape characteristics. Designers along with manufacturers achieve perfect durability and comfort balance through their weave selection to create denim products that range from casual clothing to luxury high-fashion designs.

Customization Services by LYDENIM

🎨 Looking for custom denim fabric with different textures or textured apparel? LYDENIM specializes in tailor-made solutions to meet your design and production needs.

🛍️ Explore & Get Inspired: Browse our fabric selections with various textures and discover design ideas directly on LYDENIM

🌐 Textured clothing: Myalibaba

📩 Contact Us:malone@lydenim.com

Create your denim masterpiece with LYDENIM — your trusted partner for various textured fabric and custom denim solutions.

3 thoughts on “Understanding Denim Fabric Surface Textures: Weave Structures Decoded”

Comments are closed.