डेनिम कैसे बनता है: कॉटन से जींस तक

अनुमानित पढ़ने का समय: ~10 मिनट

परिचय

डेनिम, एक वैश्विक रूप से प्रिय कपड़ा, स्थायित्व, आराम और कालातीत शैली का पर्याय है, जो पीढ़ियों से कैज़ुअल फ़ैशन को परिभाषित करता है। मज़बूत वर्कवियर के रूप में इसकी उत्पत्ति से लेकर फ़ैशन स्टेपल के रूप में इसकी स्थिति तक, डेनिम की यात्रा जटिल उत्पादन प्रक्रियाओं और विविध सामग्रियों द्वारा चिह्नित है। यह लेख डेनिम के उत्पादन, इसकी सामग्री संरचना, देखभाल तकनीकों और 2025 में उद्योग को आकार देने वाले नवीनतम रुझानों पर गहराई से चर्चा करता है। यह सामान्य प्रश्नों को भी संबोधित करता है, जैसे कि डेनिम नियमित कपास से कैसे भिन्न होता है, सेल्वेज जींस महंगी क्यों होती है, और एक जोड़ी जींस बनाने के लिए कितना पानी इस्तेमाल होता है। हमारा लक्ष्य पाठकों को इस प्रतिष्ठित कपड़े के बारे में व्यापक जानकारी देना है।

डेनिम का इतिहास

डेनिम की जड़ें 17वीं सदी के फ्रांस के नीम्स से जुड़ी हैं, जहां इसे "सर्ज डे नीम्स" के नाम से जाना जाता था। फ्रांसीसी बुनकरों द्वारा अमेरिका में लाए गए डेनिम ने अपनी मजबूती और टिकाऊपन के लिए प्रसिद्धि प्राप्त की। 1873 में, लेवी स्ट्रॉस ने डेनिम से बनी नीली जींस का पेटेंट कराया, जिसे तांबे के रिवेट्स से मजबूत किया गया, जिसने आधुनिक जींस की नींव रखी। आज, डेनिम अपने वर्कवियर मूल से आगे निकल गया है, जो वैश्विक फैशन संस्कृति की आधारशिला है।

डेनिम उत्पादन प्रक्रिया

डेनिम उत्पादन एक बहु-चरणीय प्रक्रिया है जिसमें पारंपरिक शिल्प कौशल को आधुनिक नवाचार के साथ मिश्रित किया जाता है। नीचे मुख्य चरण दिए गए हैं:

कपास की खेती और सफाई

डेनिम की यात्रा कपास के खेतों से शुरू होती है। गर्म जलवायु में उगाए जाने वाले कपास को काटा जाता है और बीज, गंदगी और अशुद्धियों को हटाने के लिए साफ किया जाता है, जिससे रेशे कताई के लिए तैयार हो जाते हैं। उच्च गुणवत्ता वाले डेनिम में अक्सर लंबे-स्टेपल कपास का उपयोग किया जाता है, जो अपनी स्थायित्व और कोमलता के लिए बेशकीमती है।

कपास की खेती और सफाई

कताई

साफ किए गए कपास के रेशों को सूत में बदला जाता है। प्रीमियम डेनिम में आमतौर पर रिंग-स्पन यार्न का इस्तेमाल किया जाता है, जिसे ओपन-एंड स्पिनिंग की तुलना में इसकी मजबूती और चिकनी बनावट के लिए महत्व दिया जाता है। यार्न की मोटाई और मोड़ कपड़े की अंतिम बनावट को प्रभावित करते हैं। स्लब यार्न, जानबूझकर अनियमितताओं के साथ, उच्च-स्तरीय डेनिम में अद्वितीय पैटर्न बनाता है।

कपास के रेशों को कताई के लिए तैयार किया गया

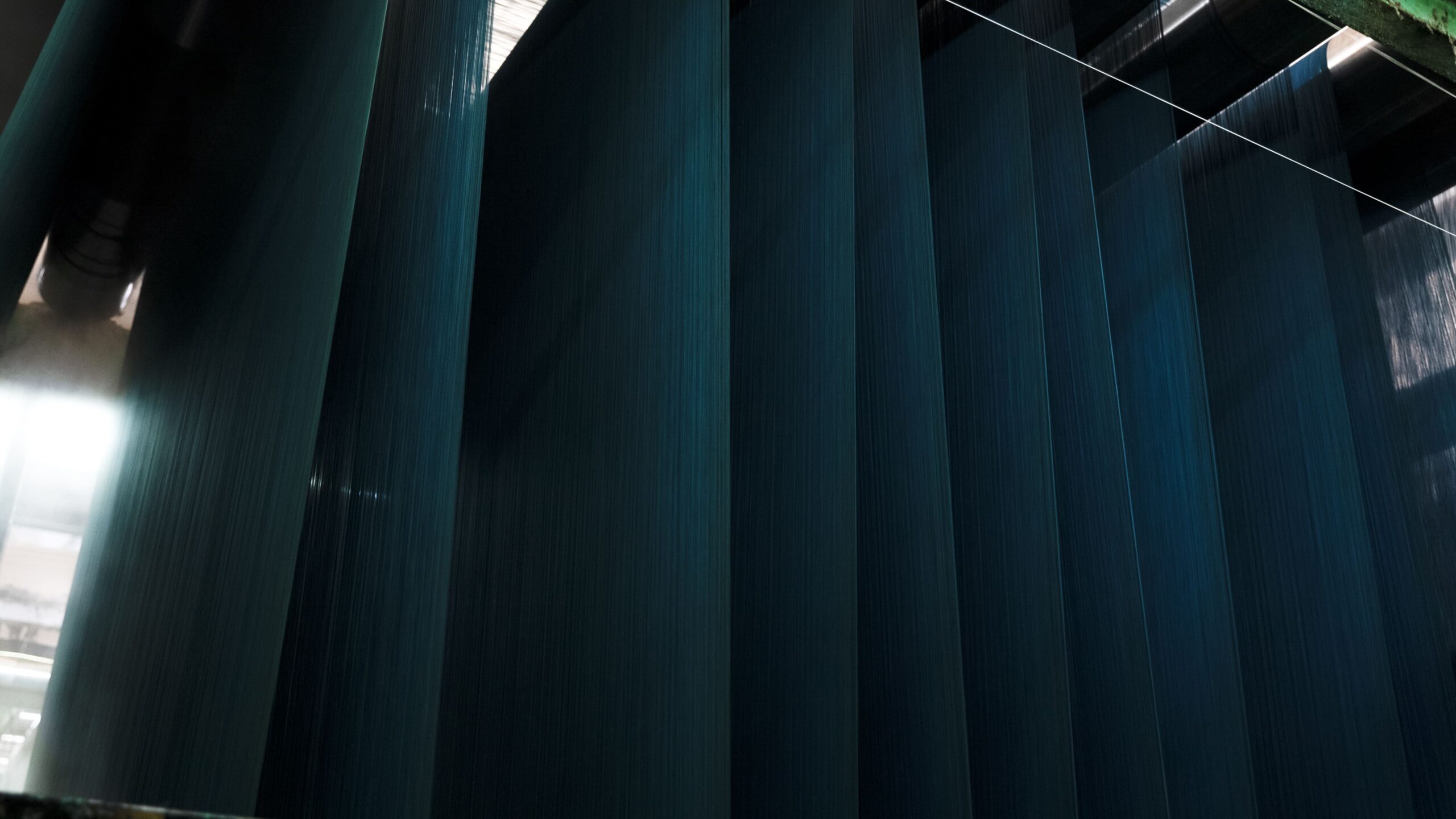

डाइंग

पारंपरिक डेनिम को इंडिगो से रंगा जाता है, ताने के धागे को रंगकर उसका विशिष्ट नीला रंग प्राप्त किया जाता है। बाने के धागे बिना रंगे या सफ़ेद रहते हैं, जिससे डेनिम की एक तरफ़ नीला और दूसरी तरफ़ सफ़ेद रंग दिखाई देता है। आधुनिक प्रक्रियाएँ काले, लाल या अन्य रंगों के लिए सल्फर डाई का उपयोग कर सकती हैं। इंडिगो के अद्वितीय फीकेपन के गुण प्रिय हैं, लेकिन बैक्टीरिया-आधारित इंडिगो जैसे संधारणीय रंग, रासायनिक उपयोग को 92% तक कम करते हैं (ह्यू टेक्नोलॉजी).

डाइंग

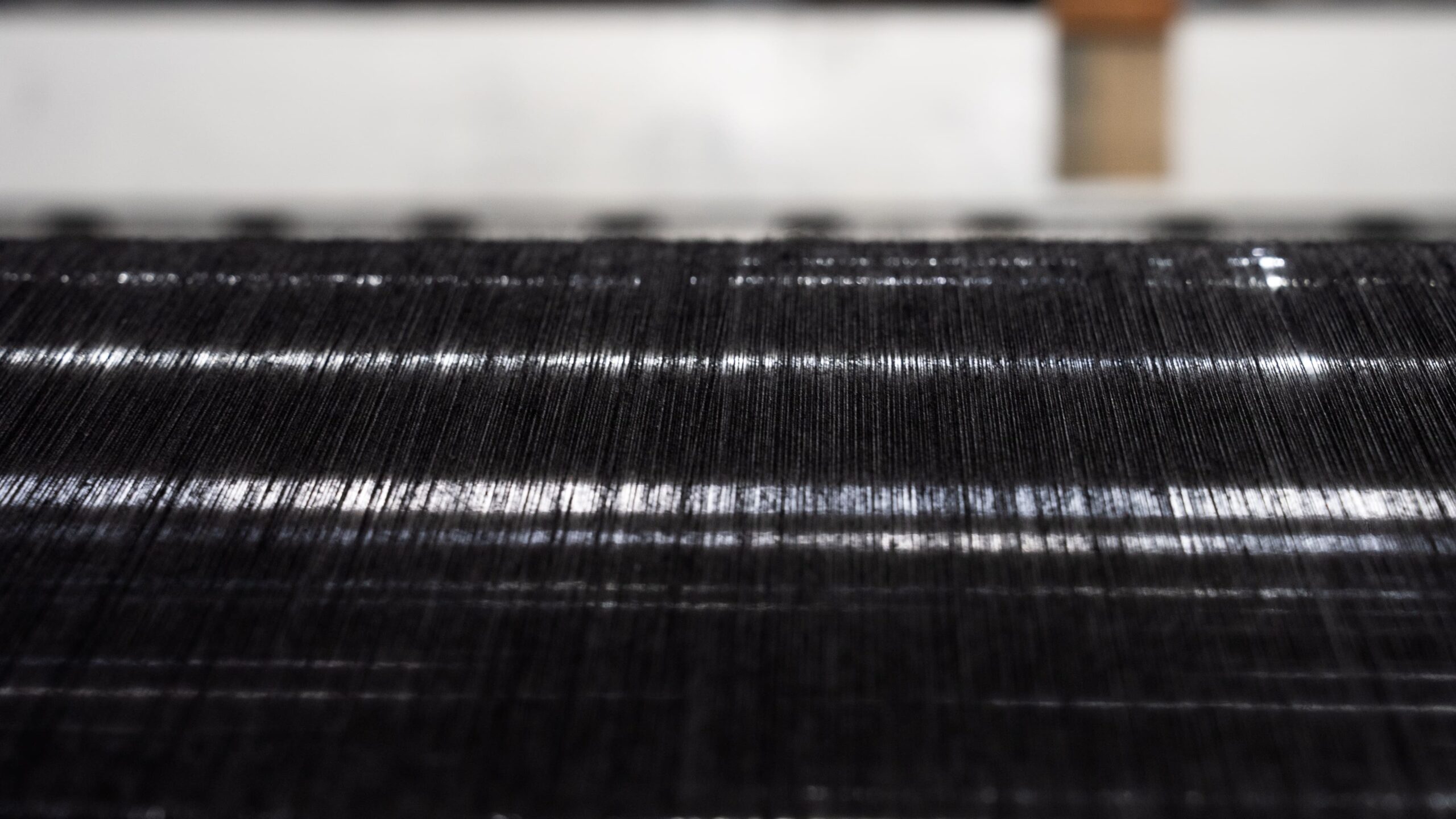

बुनाई

रंगे हुए ताने और बिना रंगे बाने के धागों को टवील पैटर्न का उपयोग करके करघे पर बुना जाता है, जहाँ बाना दो या अधिक ताने के धागों के नीचे से गुजरता है, जिससे विकर्ण लकीरें बनती हैं। यह टवील बुनाई डेनिम को मज़बूत और टिकाऊ बनाती है। पारंपरिक शटल लूम 91 सेमी की संकीर्ण चौड़ाई पर रंगीन (अक्सर लाल) किनारों के साथ सेल्वेज डेनिम का उत्पादन करते हैं। आधुनिक शटललेस लूम व्यापक कपड़ा (152 सेमी) बनाते हैं, जिससे दक्षता बढ़ती है लेकिन सेल्वेज की कमी होती है।

| बुनाई का प्रकार | विशेषताएँ | अनुप्रयोग |

|---|---|---|

| 3×1 ट्विल | प्रमुख विकर्ण लकीरें | क्लासिक जींस |

| 2×1 ट्विल | महीन टवील रेखाएँ | हल्के वजन वाली गर्मियों की जींस |

| टूटा हुआ टवील | ज़िगज़ैग पैटर्न | पैर मुड़ने से रोकता है |

परिष्करण प्रक्रियाएं

बुनाई के बाद, डेनिम अपनी कार्यक्षमता, दिखावट और आराम को बढ़ाने के लिए कई तरह की परिष्करण प्रक्रियाओं से गुजरता है। ये उपचार आयामी स्थिरता, बनावट और सौंदर्य गुणों को संबोधित करते हैं, जिससे कपड़े को परिधान निर्माण के लिए तैयार किया जाता है। मुख्य परिष्करण प्रक्रियाओं में शामिल हैं:

-

सिंगिंगढीले रेशों या बालों को जलाने के लिए कपड़े को आग के ऊपर से गुजारा जाता है, जिसके परिणामस्वरूप सतह चिकनी हो जाती है और पिलिंग कम हो जाती है (फाइबर2फैशन)।

-

डिसाइजिंगयदि सूत को मजबूत करने के लिए बुनाई के दौरान साइजिंग एजेंट (जैसे, स्टार्च) का प्रयोग किया गया था, तो डीसाइजिंग उन्हें हटा देती है ताकि कपड़े को आगे के उपचार के लिए तैयार किया जा सके।

-

दस्तइस प्रक्रिया में कपास के रेशों से प्राकृतिक मोम, तेल और अशुद्धियों को हटाने के लिए डिटर्जेंट और क्षार का उपयोग किया जाता है, जिससे अवशोषण और सफाई में सुधार होता है।

-

ब्लीचिंगहल्के रंगों या सफ़ेद डेनिम के लिए, ब्लीचिंग से प्राकृतिक कॉटन का रंग निकल जाता है। पारंपरिक नीले डेनिम के लिए यह चरण आमतौर पर छोड़ दिया जाता है।

-

मर्सराइजेशनकपड़े को सोडियम हाइड्रोक्साइड से उपचारित करने से रेशे की मजबूती, चमक और रंगाई की अनुकूलता बढ़ जाती है, हालांकि वांछित सौंदर्य के आधार पर यह वैकल्पिक है।

-

सैनफोरिज़ेशन (पूर्व-सिकुड़न): कपड़े को खींचा और दबाया जाता है ताकि सिकुड़न कम से कम हो, जिससे यह सुनिश्चित हो सके कि कपड़े धोने के बाद भी आकार और आकृति में बने रहें। अधूरा डेनिम 10-12% तक सिकुड़ सकता है, जबकि सैनफोराइज़्ड डेनिम 0-4% (डेनिम्स और जींस) तक सिकुड़न को सीमित करता है।

-

नरम करने वाले उपचारहल्की धुलाई या एंजाइम उपचार से कपड़ा नरम हो जाता है, जिससे भारी घर्षण के बिना हाथ का अनुभव बेहतर हो जाता है।

-

कैलेंडरिंगकपड़े को गर्म रोलर्स से गुजारने से सतह चिकनी हो जाती है या उसमें हल्की चमक आ जाती है।

-

कार्यात्मक खत्मजल प्रतिरोधकता या झुर्रियाँ प्रतिरोधकता जैसे उपचार प्रदर्शन को बढ़ाते हैं।

-

लेजर वॉशिंग: लुप्त होती या कष्टदायक प्रभाव पैदा करने के लिए लेज़र का उपयोग करने वाली एक स्थायी विधि, पारंपरिक धुलाई की तुलना में 80% तक पानी के उपयोग को कम करती है, जिसमें प्रति जोड़ा लगभग 1,500 लीटर की खपत होती है ([संयुक्त राष्ट्र 2023 डेटा]([अमान्य यूआरएल, उद्धृत न करें]))।

परिष्करण प्रक्रियाएं

परिधान विनिर्माण

एक बार तैयार होने के बाद, डेनिम कपड़े को जींस, जैकेट या स्कर्ट जैसे कपड़ों में बदल दिया जाता है। इस चरण में कपड़े की गुणवत्ता को बनाए रखने के लिए सटीक शिल्प कौशल शामिल है। मुख्य चरणों में शामिल हैं:

-

पैटर्न बनानाउचित फिट और सौंदर्य सुनिश्चित करने के लिए विभिन्न आकारों और शैलियों के लिए पैटर्न डिजाइन करना।

-

काटनाडेनिम को टुकड़ों में काटने के लिए पैटर्न का उपयोग करना, अक्सर सटीकता और दक्षता के लिए स्वचालित कटिंग मशीनों के साथ।

-

सिलाईसिलाई मशीनों का उपयोग करके कटे हुए टुकड़ों को कपड़ों में जोड़ना, जिसमें मुख्य भाग का निर्माण, जेबें, कमरबंद और अन्य घटक जोड़ना शामिल है।

-

हार्डवेयर अटैचमेंट: टिकाऊपन और शैली के लिए बटन, YKK ज़िपर, तांबे के रिवेट्स, बेल्ट लूप और लेबल जैसे कार्यात्मक और सजावटी तत्वों को जोड़ना।

सिलाई

परिष्करण

बनाने के बाद, डेनिम को नरम करने के लिए धुलाई (जैसे, स्टोन या एंजाइम वॉश) की जाती है या लोच के लिए स्पैन्डेक्स जैसे स्ट्रेच फाइबर जोड़े जाते हैं। अन्य उपचारों में सिकुड़न को कम करने के लिए सैनफोराइजेशन, चमक के लिए कैलेंडरिंग या पानी के प्रतिरोध के लिए कोटिंग्स शामिल हैं।

डेनिम जींस धुलाई

गारमेंट उत्पादन

तैयार डेनिम को काटकर जींस, जैकेट या स्कर्ट जैसे कपड़ों में सिल दिया जाता है। इस प्रक्रिया में पैटर्न बनाना, काटना, सिलाई करना और बटन, ज़िपर या रिवेट्स जोड़ना शामिल है। मैनुअल तरीकों की तुलना में लेजर कटिंग से 15% कपड़े की बचत होती है। पारंपरिक सिंगल-नीडल लॉकस्टिच का उपयोग विंटेज स्टाइल के लिए किया जाता है, जबकि ओवरलॉक मशीनें फास्ट फैशन के लिए उपयुक्त हैं। कढ़ाई, डिस्ट्रेसिंग या व्हिस्करिंग जैसी सजावटी तकनीकें व्यक्तित्व को जोड़ती हैं।

जींस प्रसंस्करण

डेनिम सामग्री संरचना

डेनिम एक टिकाऊ टवील-बुना कपड़ा, मुख्य रूप से से बना 100 % कपास (ताने के धागे को नील रंग से रंगा जाता है, बाने को सफेद छोड़ दिया जाता है)। आधुनिक रूपों में शामिल हो सकते हैं 1–3 % इलास्टेन/स्पैन्डेक्स पॉलिएस्टर/लियोसेल के खिंचाव या छोटे परिवर्धन के लिए।

डेनिम के घटक इसके प्रदर्शन और सौंदर्य को परिभाषित करते हैं। नीचे प्राथमिक तत्व दिए गए हैं:

प्राथमिक सामग्री: कपास

डेनिम मुख्य रूप से कॉटन से बना होता है, जिसमें लंबे-स्टेपल वाली किस्में टिकाऊपन और कोमलता के लिए पसंद की जाती हैं। कॉटन की गुणवत्ता सीधे डेनिम के जीवनकाल और आराम को प्रभावित करती है। 100% कॉटन डेनिम सांस लेने योग्य है और खूबसूरती से फीका पड़ता है, पारंपरिक जींस के लिए आदर्श है।

कपास

रंगों

इंडिगो, इंडिगो पौधे से प्राप्त होता है, यह डेनिम का क्लासिक रंग है, जो विशिष्ट फीकेपन के साथ नीला रंग प्रदान करता है। आधुनिक डेनिम में काले, भूरे या अन्य रंगों के लिए सल्फर डाई का उपयोग किया जा सकता है, जो इंडिगो के पानी का आठवां हिस्सा खपत करता है। बैक्टीरियल इंडिगो जैसे नवाचार रासायनिक उपयोग को कम करते हैं, जो स्थिरता लक्ष्यों के साथ संरेखित होते हैं।

अतिरिक्त फाइबर

आधुनिक मांगों को पूरा करने के लिए, डेनिम में अक्सर सिंथेटिक फाइबर शामिल होते हैं:

- स्पैन्डेक्स (2-5%): 98% शेप रिकवरी के साथ, स्किनी जींस में आम तौर पर मिलने वाले खिंचाव को बढ़ाता है।

- पॉलिएस्टर: आकार प्रतिधारण और स्थायित्व को बढ़ाता है।

- टेन्सेल® या पुनर्नवीनीकृत पॉलिएस्टरपर्यावरणीय प्रभाव को कम करने के लिए पर्यावरण अनुकूल कपड़ों में उपयोग किया जाता है।

मिश्रित फाइबर आराम को बेहतर बनाते हैं, लेकिन शुद्ध सूती डेनिम की बनावट से समझौता कर सकते हैं।

यार्न के प्रकार

डेनिम में आमतौर पर 30% अधिक मजबूती और एकरूपता के लिए रिंग-स्पन यार्न का उपयोग किया जाता है। ओपन-एंड यार्न सस्ता है लेकिन कम टिकाऊ है। स्लब यार्न से बनावट वाला, कलात्मक डेनिम बनता है, जो प्रीमियम लाइनों में लोकप्रिय है।

सामान

- धागा: पॉली-कॉटन कोर-स्पन धागा, टिकाऊ और मजबूत।

- हार्डवेयरतांबे के रिवेट्स और YKK ज़िपर कार्यक्षमता और सौंदर्य को बढ़ाते हैं।

| फाइबर प्रकार | विशेषताएँ | अनुप्रयोग |

|---|---|---|

| 100% कॉटन | सांस लेने योग्य, बढ़िया फीकापन | पारंपरिक जींस |

| कपास + स्पैन्डेक्स | खिंचावदार, आकार में फिट होने वाला | सांकरी जीन्स |

| कपास + पॉलिएस्टर | टिकाऊ, आकार बनाए रखने वाला | कार्यात्मक परिधान |

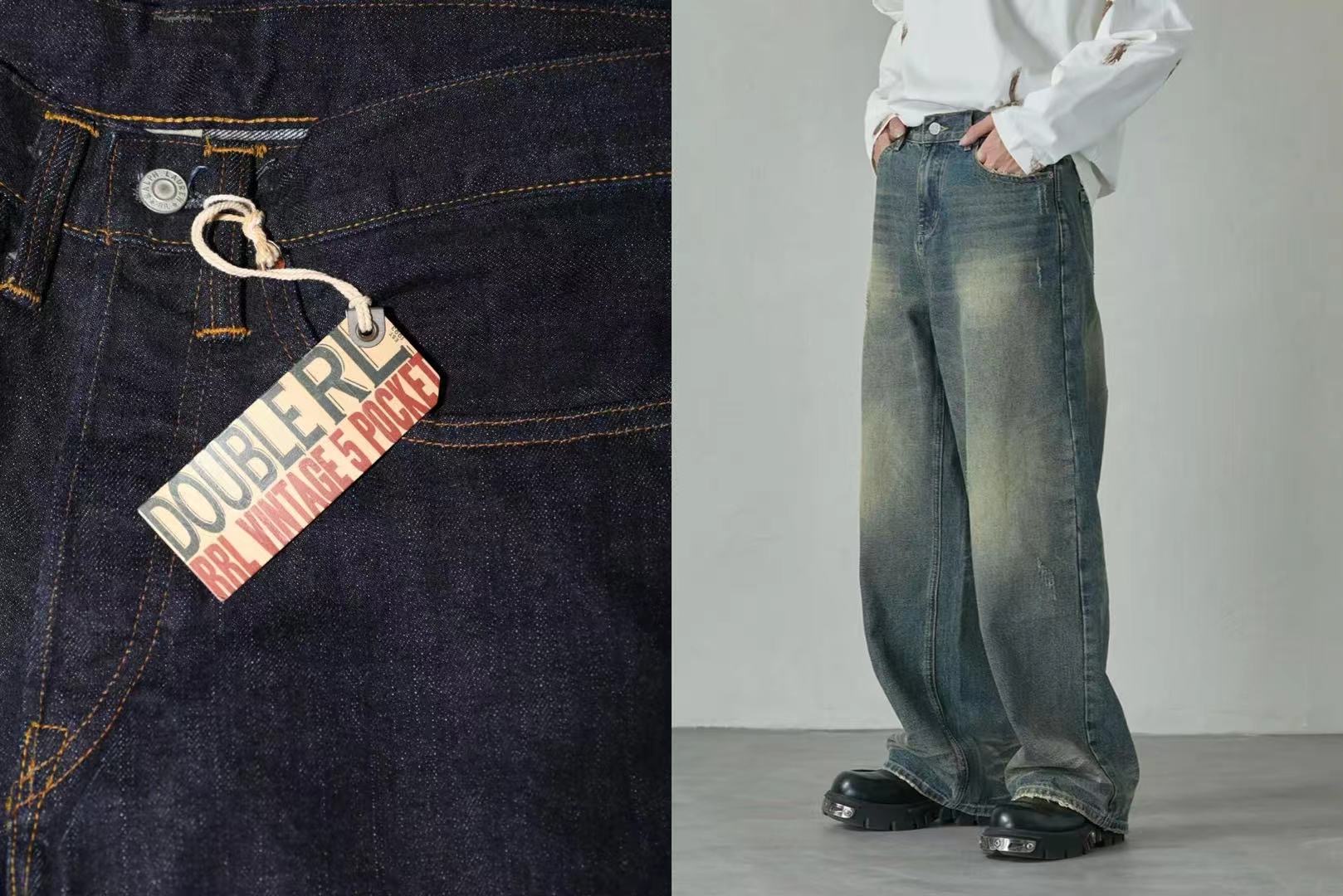

2025 डेनिम ट्रेंड्स

2025 में, डेनिम नवाचार और स्थिरता के साथ विकसित होगा (फैशनयुनाइटेड):

- कपड़ा नवाचारउन्नत धुलाई तकनीक और मुलायम स्पर्श वाले कपड़े हाथ में महसूस होने वाले एहसास, टिकाऊपन और आराम को बढ़ाते हैं। एंजाइम वॉश से रसायनों का इस्तेमाल कम होता है और हाथ में महसूस होने वाला एहसास मुलायम होता है।

- छायामहिलाओं के लिए वाइड-लेग जींस और पुरुषों के लिए स्ट्रेट-लेग जींस का बोलबाला है, जिसमें मिड-राइज डिजाइन सभी प्रकार के शरीर के लिए आराम और संरचना का संतुलन प्रदान करते हैं।

- वहनीयता: ब्रांड बर्बादी को रोकने के लिए कालातीत, टिकाऊ उत्पादों को प्राथमिकता देते हैं। पानी रहित रंगाई और पुनर्चक्रण से पानी का उपयोग 96% तक कम हो जाता है (उदाहरण के लिए, लेवी का पानी

- रंग रुझानसूर्य की रोशनी से फीके पड़े नीले, परिष्कृत तटस्थ और कुरकुरे सफेद रंग बहुमुखी प्रतिभा और क्लासिक अपील प्रदान करते हैं, जो विभिन्न परिधानों के साथ सहजता से मेल खाते हैं।

डेनिम बनाम अन्य कपड़े

डेनिम की टवील बुनाई इसे सादे-बुनाई वाले कॉटन (जैसे, पॉपलिन) से अलग बनाती है, जिससे यह कठोर उपयोग के लिए अधिक मोटा और अधिक टिकाऊ हो जाता है। नियमित कॉटन हल्का होता है, जो शर्ट के लिए उपयुक्त होता है। नकली डेनिम, अक्सर पॉलिएस्टर, डेनिम के लुक की नकल करता है, लेकिन इसमें इसकी स्थायित्व और प्राकृतिक एहसास की कमी होती है। डेनिम की टवील तनाव को वितरित करती है, सादे बुनाई पर फाड़ प्रतिरोध को बढ़ाती है।

डेनिम की विशेषताएँ और देखभाल

डेनिम के अनूठे गुण इसे पसंदीदा बनाते हैं, लेकिन उचित देखभाल से इसकी दीर्घायु सुनिश्चित होती है।

विशेषताएँ

- सहनशीलता: ट्विल बुनाई फटने से बचाती है, कार्यस्थल और दैनिक उपयोग के लिए आदर्श है।

- लुप्त होतीनील रंग समय के साथ फीके पड़ जाते हैं, जिससे व्यक्तिगत पैटर्न बनते हैं।

- संकुचनकच्चा डेनिम (बिना धोया हुआ) सिकुड़ सकता है; पहनने से पहले ठंडे पानी में धो लें।

- खींचनास्पैन्डेक्स-मिश्रित डेनिम पतली शैलियों के लिए बेहतर फिट प्रदान करता है।

देखभाल संबंधी सुझाव

- धुलाई: हल्के डिटर्जेंट के साथ ठंडे पानी में अंदर से बाहर की ओर धोएं, ब्लीच से बचें।

- सुखानेसिकुड़न को रोकने के लिए हवा में सुखाएं या कम गर्मी का प्रयोग करें।

- इस्त्रीयदि आवश्यक हो तो धीमी आंच पर अंदर से बाहर की ओर प्रेस करें।

- भंडारण: रंग उड़ने से बचाने के लिए सीधे सूर्य की रोशनी से बचाते हुए लटकाएं या मोड़ें।

- जमनाकुछ लोग जींस को ठंडा करके धोने की मात्रा कम करने और बैक्टीरिया को मारने का सुझाव देते हैं, लेकिन इसका प्रभाव सीमित है; सावधानी से उपयोग करें (यूएनईपी).

कच्ची डेनिम बनाम प्री-वॉश्ड जींस

कच्चे डेनिम, बिना धुले और बिना उपचारित, शुरू में कठोर होते हैं लेकिन समय के साथ शरीर के हिसाब से ढल जाते हैं, और अपने अनोखे फीके पैटर्न के लिए बेशकीमती होते हैं। पहले से धुले जींस मुलायम और पहनने के लिए तैयार होते हैं। कच्चे डेनिम अपनी अनुकूलन क्षमता के कारण उत्साही लोगों को आकर्षित करते हैं।

सेल्वेज डेनिम

पारंपरिक शटल लूम पर बुने जाने वाले सेल्वेज डेनिम में रंगीन किनारे (अक्सर लाल) होते हैं, जो उखड़ने से बचाते हैं। इसकी संकीर्ण 91 सेमी चौड़ाई और 40% कटिंग अपशिष्ट, धीमी उत्पादन (0.5 मीटर/मिनट) के साथ मिलकर उच्च लागत को बढ़ावा देते हैं।

अक्सर पूछे जाने वाले प्रश्नों

नीचे उपयोगकर्ता द्वारा पूछे गए कुछ प्रश्नों के उत्तर दिए गए हैं:

- क्या जींस कपास से बनी होती है? हां, जींस मुख्य रूप से सूती होती है, लेकिन आधुनिक शैलियों में खिंचाव या स्थायित्व के लिए स्पैन्डेक्स या पॉलिएस्टर शामिल हो सकते हैं।

- एक जोड़ी जींस बनाने के लिए कितने पानी की आवश्यकता होती है? अनुमान है कि इसकी मात्रा 3,781 से 7,600 लीटर तक है, जो मुख्य रूप से कपास की खेती और रंगाई के लिए है।

- लेवीज़ की “मेड इन यूएसए” जींस का उत्पादन कहां होता है? 2025 तक, लेवीज़ ने अमेरिका में प्रतिष्ठित 501 जींस का उत्पादन बंद कर दिया है, तथा चीन, बांग्लादेश और अन्य देशों में उत्पादन शुरू कर दिया है।

- क्या डेनिम, जींस और लेवीज़ एक ही हैं? डेनिम एक कपड़ा है, जींस डेनिम से बने वस्त्र हैं, और लेवीज़ एक ब्रांड है; वे अलग हैं।

- रंगाई से पहले डेनिम कैसा दिखता है? बिना रंगे डेनिम सफेद या प्राकृतिक सूती रंग का होता है, जो बिना रंगे ताने के कारण थोड़ा सफेद रंग का होता है।

- जींस क्यों सिकुड़ जाती है? कपास के रेशे गीले या गर्म परिस्थितियों में सिकुड़ जाते हैं, विशेष रूप से अनुपचारित कच्चे डेनिम में।प्रासंगिक ज्ञान

- डेनिम और ट्विल में क्या अंतर है? ट्विल एक प्रकार की बुनाई है; डेनिम एक विशिष्ट ट्विल कपड़ा है, जो आमतौर पर इंडिगो रंग के साथ सूती कपड़ा होता है।प्रासंगिक ज्ञान

- जींस सिलना कितना आसान है? जींस की सिलाई के लिए विशेष उपकरण और कौशल की आवश्यकता होती है, क्योंकि कपड़ा मोटा होता है और सिलाई जटिल होती है, जो शुरुआती लोगों के लिए चुनौतीपूर्ण होती है।

- क्या जींस को सचमुच धोया नहीं जा सकता? जींस को धोया जा सकता है, लेकिन कच्चे डेनिम को अक्सर कम धोया जाता है ताकि उसका रंग फीका न पड़े; नियमित जींस की देखभाल के लिए दिशानिर्देशों का पालन किया जाता है।प्रासंगिक ज्ञान

- सेल्वेज जींस महंगी क्यों होती है? सेल्वेज डेनिम में धीमी शटल लूम का उपयोग किया जाता है, इसमें कटिंग अपशिष्ट (40%) अधिक होता है, तथा इसमें मानक डेनिम की तुलना में तिगुना श्रम लगता है।

निष्कर्ष

डेनिम का उत्पादन, सामग्री और देखभाल कपड़े के रूप में इसकी बहुमुखी प्रतिभा को रेखांकित करती है। कपास के खेतों से लेकर तैयार कपड़ों तक, प्रत्येक चरण इसकी गुणवत्ता और पर्यावरण पदचिह्न को आकार देता है। 2025 में, डेनिम उद्योग नवाचार और स्थिरता को अपनाता है, यह सुनिश्चित करता है कि यह क्लासिक कपड़ा आधुनिक जरूरतों को पूरा करता है। इसके उत्पादन और देखभाल को समझकर, उपभोक्ता सूचित विकल्प बना सकते हैं, अपने डेनिम को बनाए रख सकते हैं और पर्यावरण के प्रति जागरूक प्रथाओं का समर्थन कर सकते हैं।

अनुकूलन सेवाएँ: आपका डेनिम, आपके नियम

आधुनिक तकनीक पारंपरिक बाधाओं के बिना कस्टम डेनिम बनाने में सक्षम बनाती है:

कपड़ों का अन्वेषण करें: lydenim.com

डिजाइन प्रेरणा: अलीबाबा लांगयुआनटेक्सटाइल

संपर्क करना: malone@lydenim.com विशिष्ट प्रश्नों के लिए.