Rope Dyeing vs Slasher Dyeing: Which Denim Technique Wins?

Estimated reading time: ~3 minutes

Introduction

When you think of denim—whether it’s a classic pair of jeans, a stylish denim jacket, or even denim fabric by the yard for your next DIY project—its iconic blue hue and unique fade are likely what come to mind. But have you ever wondered how is denim fabric made to achieve that signature look? The secret lies in the dyeing process, and two techniques dominate the industry: rope dyeing and slasher dyeing. In this post, we’ll break down the differences, advantages, and why one might suit your denim needs better than the other.

What Is Denim Fabric and Why Dyeing Matters

Denim is a sturdy cotton twill fabric, traditionally woven with indigo-dyed warp threads and undyed weft threads, giving it that classic blue-and-white appearance. The dyeing process is critical because it determines how the fabric looks, wears, and fades over time—key factors for denim lovers. Let’s dive into the two main methods.

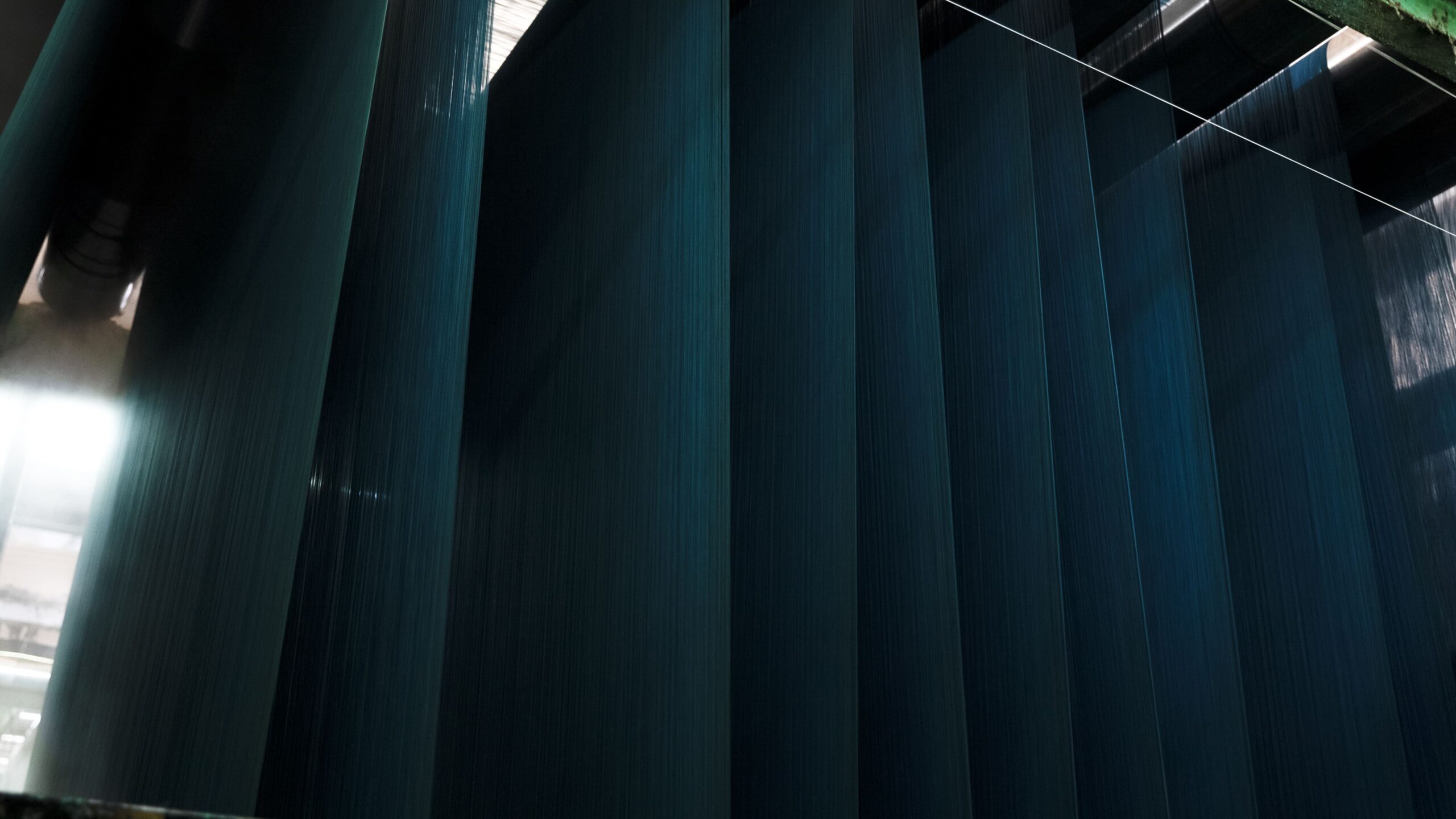

Rope Dyeing: The Fade King

Rope dyeing is a traditional method where yarns are twisted into ropes (typically 300-400 strands) before being dipped into indigo dye baths multiple times. Here’s why it’s a favorite:

- Superior Fade Effect: Rope dyeing creates a “ring dye” effect, where only the outer layer of the yarn is dyed, leaving the core white. This leads to stunning fades as the denim wears—perfect for that vintage look.

- High Production Capacity: It’s efficient for large-scale denim fabric production, making it ideal for manufacturers.

- Better Color Consistency: The tension in the ropes ensures even dye penetration, reducing shade variation and delivering richer, deeper blues.

- Eco-Friendly Edge: It uses less reducing agent and dye concentration, plus it generates less yarn waste.

Rope Dyeing

Slasher Dyeing: Flexibility Meets Finesse

Slasher dyeing (or sheet dyeing) involves spreading yarns into a flat sheet and passing them through dye baths. It’s a modern alternative with its own strengths:

- Gentler on Yarn: Less tension makes it perfect for finer yarn counts, ideal for lightweight denim fabric or stretch denim fabric by the yard.

- Color Variety: The even sheet dyeing allows for more flexibility in achieving consistent, vibrant colors beyond traditional indigo.

- Lower Minimums: It’s great for smaller batches, appealing to boutique producers or custom projects.

- Energy Efficiency: It typically consumes less energy, making it a greener option in some setups.

Dyeing

Rope Dyeing vs. Slasher Dyeing: The Showdown

| Feature | Rope Dyeing | Slasher Dyeing |

|---|---|---|

| Fade Quality | Excellent (ring dye effect) | Moderate (less pronounced fades) |

| Production Scale | High capacity | Better for smaller runs |

| Yarn Tension | Higher, more even penetration | Lower, gentler on fine yarns |

| Color Flexibility | Best for deep indigo shades | More versatile for varied colors |

| Sustainability | Less dye and waste | Lower energy use |

Which Should You Choose?

- For Classic Denim Lovers: If you’re after that authentic, fade-heavy denim fabric—think selvedge denim or raw denim—rope dyeing is your go-to. Its consistency and fade potential make it a staple for premium jeans.

- For Creative Projects: Need denim fabric by the yard for a unique design or lightweight piece? Slasher dyeing’s flexibility and suitability for finer yarns might be the better pick.

Final Thoughts

Both rope dyeing and slasher dyeing have their place in the world of denim fabric production. Your choice depends on the look, feel, and purpose of your denim—whether it’s a rugged pair of jeans or a vibrant upholstery fabric. Curious to explore high-quality denim options or learn more about what fabric is denim made of? Check out lydenim.com for premium denim fabrics, or reach out to Malone@l denim.com for expert advice tailored to your needs.

Customization Services by LYDENIM

🎨 Want custom denim fabrics or unique custom denim garment? LYDENIM specializes in tailor-made solutions to meet your design and production needs.

🛍️ Explore & Get Inspired: Browse our fabric selections and discover design ideas on LYDenim.

🌐 Elastic Clothing: Check out our offerings on MyAlibaba. 📩 Contact Us: Reach out at malone@lydenim.com.

Create your denim masterpiece with LYDENIM—your trusted partner for stretch fabric and custom denim solutions.