The Art of Spinning Denim Yarn

Estimated reading time: ~3 minutes

Introduction

Denim is more than just a fabric—it’s a cultural icon, loved for its durability and timeless appeal. But have you ever wondered how denim is made? At the heart of this process lies spinning, the critical step that transforms raw fibers into the sturdy yarn that defines denim fabric. In this post, we’ll dive into the spinning process, explore the two main methods—ring spinning and open-end spinning—and explain why ring spinning has reclaimed its throne in the denim industry.

What Is Spinning?

Spinning is the process of turning loose fibers, typically cotton, into yarn. This yarn forms the foundation of denim fabric, giving it strength and character. The process involves two key stages: preparation and spinning. Let’s break it down.

Stage 1: Preparation

Before spinning begins, the fibers must be prepped. This stage involves:

- Parallelizing: Aligning the fibers so they lie in the same direction.

- Elongating: Stretching the fibers to maximize their length.

The goal? To create a uniform, durable base for the yarn. By leveraging the full length of the fibers, manufacturers ensure the resulting yarn is strong enough to withstand the rigors of denim production and wear.

Cotton fibers prepped for spinning

Stage 2: Spinning

Once prepared, the fibers enter the spinning phase, where they’re twisted together to form yarn. This is where the two primary methods—ring spinning and open-end spinning—come into play.

Ring Spinning

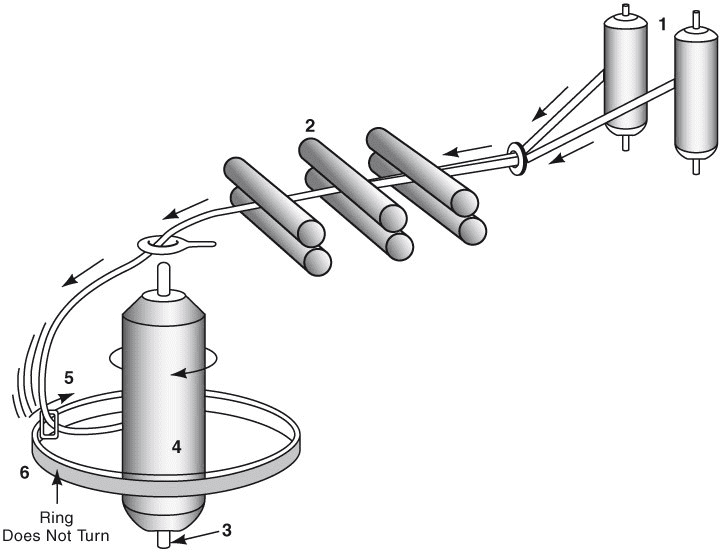

Ring spinning is the traditional method that dominated denim production until the 1970s. Here’s how it works:

- Prepared fibers are fed through a series of rollers.

- A ring and traveler mechanism twists the fibers into yarn, creating a tight, consistent structure.

- The result? A smoother, stronger yarn with a distinct texture.

Ring spinning fell out of favor briefly but has made a comeback thanks to its ability to produce high-quality, “authentic” denim—especially for stretch denim varieties.

Open-End Spinning (Rotor Spinning)

Introduced in the 1970s, open-end spinning, or rotor spinning, offered a faster, more cost-effective alternative:

- Fibers are fed into a rotor, where high-speed rotation twists them into yarn.

- No ring or traveler is needed, speeding up production.

- The yarn is slightly bulkier and less uniform than ring-spun yarn.

While efficient, open-end spinning often sacrifices some of the durability and finesse that denim enthusiasts crave.

Ring spinning

Why Ring Spinning Wins Today

Since the 1970s, the denim industry has shifted. The rise of stretch denim and a renewed demand for vintage-style, authentic denim have put ring spinning back in the spotlight. Why?

- Strength: Ring-spun yarn is more durable, perfect for long-lasting jeans.

- Texture: It offers a richer, more tactile feel that mimics classic denim.

- Versatility: It pairs well with modern stretch fibers, meeting today’s fashion demands.

From Yarn to Denim Fabric

After spinning, the yarn is woven into denim fabric, typically using a twill weave that creates denim’s signature diagonal pattern. This fabric then undergoes dyeing (often with indigo) and finishing processes to become the jeans, jackets, and skirts we love.

loom

Conclusion

Spinning is the unsung hero of denim production, bridging raw fibers and finished fabric. Whether it’s the robust charm of ring spinning or the efficiency of open-end spinning, this process defines the denim fabric we wear every day. Want to explore premium denim made with cutting-edge spinning techniques? Visit lydenim.com or reach out to Malone@lydenim.com for more insights!

Customization Services by LYDENIM

🎨 Want custom denim fabrics or unique custom denim garment? LYDENIM specializes in tailor-made solutions to meet your design and production needs.

🛍️ Explore & Get Inspired: Browse our fabric selections and discover design ideas on LYDenim.

🌐 Elastic Clothing: Check out our offerings on MyAlibaba. 📩 Contact Us: Reach out at malone@lydenim.com.

Create your denim masterpiece with LYDENIM—your trusted partner for stretch fabric and custom denim solutions.