A Deep Dive into the Spinning Process

Estimated reading time: ~2 minutes

Introduction

Denim is more than just a fabric—it’s a lifestyle, a symbol of durability and style. But have you ever wondered, what is denim fabric made of and how denim is made? The journey from raw cotton to the rugged denim fabric we love begins with an intricate spinning process. In this post, we’ll explore the two key stages of spinning—preparation and torsion—and uncover how techniques like ring spinning create everything from classic denim to stretch denim fabric. Let’s dive in!

Stage 1: Preparing the Cotton Fibers

The magic starts with raw cotton fibers, which need to be cleaned, aligned, and elongated before they can become yarn. This preparation stage ensures the fibers are ready to produce strong, durable denim fabric.

- Bale Plucking: It all begins with the bale plucker, a machine that grabs cotton fibers from bales. These fibers are then mixed and cleaned to remove impurities like leftover seeds from the ginning process.

Bale Plucking

- Carding: Next, the fibers enter the carding machine. Here, two cylinders covered in needles rotate at different speeds, combing the cotton into a fluffy rope called a sliver. This step starts aligning the fibers parallel to each other.

Carding

- Drawing: The slivers then move to the drawing frame, where six slivers are combined and stretched by rollers spinning at increasing speeds. This process can repeat, merging up to 36 slivers into one long, thin strand. The result? Fibers that are elongated sixfold, ready for spinning.

Cotton fibers prepped for spinning

Stage 2: Spinning the Yarn with Torsion

Once prepared, the fibers undergo torsion—the actual spinning that twists them into yarn. This is where denim’s strength and character come to life, with two main methods standing out.

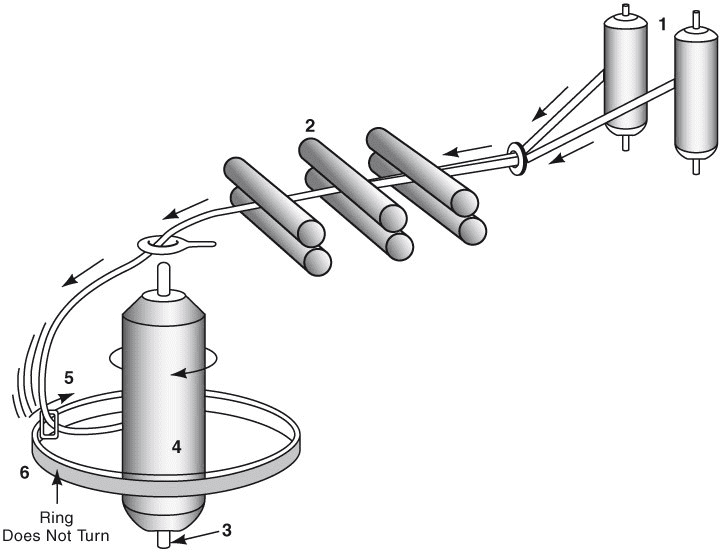

- Ring Spinning: In this traditional method, the sliver is fed into roving frames for initial twisting. It then passes through drafting rollers, forming a thin ribbon. A rotating spindle and a tiny clip called the ring traveller twist the yarn further as it winds onto a bobbin (or ring cop). This process creates the robust yarn used in classic denim fabric.

Ring spinning

- Stretch Denim Fabric: For those comfy stretch jeans, ring spinning gets an upgrade. A synthetic elastomer (like spandex) is spun into the yarn’s core, with cotton wrapped around it. This keeps the soft feel and fading potential of cotton while adding stretchability—perfect for modern denim lovers.

Why It Matters: From Yarn to Denim Fabric

The spinning process defines denim’s texture, strength, and versatility. Ring-spun yarn gives denim its rugged, authentic look, while stretch denim fabric offers flexibility for everyday wear. Whether you’re curious about how denim is made or shopping for denim fabric by the yard, understanding this process highlights the craftsmanship behind every pair of jeans.

Customization Services by LYDENIM

🎨 Want custom denim fabrics or unique custom denim garment? LYDENIM specializes in tailor-made solutions to meet your design and production needs.

🛍️ Explore & Get Inspired: Browse our fabric selections and discover design ideas on LYDenim.

🌐 Elastic Clothing: Check out our offerings on MyAlibaba. 📩 Contact Us: Reach out at malone@lydenim.com.

Create your denim masterpiece with LYDENIM—your trusted partner for stretch fabric and custom denim solutions.