Ultimate Denim Fabric Quality Control Checklist: 10 Tips

Estimated reading time: ~5 minutes

Denim fabric quality control is essential for garment factories aiming to produce high-quality jeans, jackets, and other apparel that meets customer expectations. In a competitive market valued at USD 27.1 billion in 2022 and projected to reach USD 36 billion by 2027, implementing a robust denim fabric quality control system helps detect issues early, minimize waste, and enhance overall efficiency. This guide provides a comprehensive checklist with 10 key tips to elevate your production standards, backed by industry data showing that effective controls can reduce fabric waste by up to 30% in garment production.

Whether you’re sourcing from suppliers or managing in-house processes, prioritizing denim fabric quality control ensures compliance with industry standards like ASTM and ISO. By focusing on inspections, testing, and defect prevention, factories can build a reputation for durability and comfort, leading to loyal customers and long-term success. Studies indicate that without proper controls, sewing defect rates in denim pants can reach 63.6%, with human errors accounting for 63.2% of issues.

Understanding the Basics of Denim Fabric Quality Control

Denim fabric quality control begins with thorough sourcing and inspection procedures. Garment manufacturers must evaluate fabric properties such as texture, color consistency, and durability before production starts. A well-structured checklist acts as a roadmap, helping teams identify defects like tears, uneven dyeing, or inconsistencies in weight. Industry audits reveal that material defects contribute to 39.3% of customer claims, which average 1.3% of total jeans sold.

For instance, using automated inspection systems can streamline denim fabric quality control by measuring weight and density accurately. This not only reduces human error but also improves manufacturing speed. Factories that adopt these practices often see a significant drop in waste, contributing to sustainable operations amid the garment industry’s contribution to 10% of global CO2 emissions.

Denim Fabric Quality Control

Key Components of a Denim Fabric Quality Control Checklist

To achieve consistent results, incorporate these 10 essential tips into your denim fabric quality control routine:

- Inspect Fabric Weight and Thickness: Ensure uniformity to avoid issues in fit and comfort. Use digital scales for precise measurements, targeting weights from 8.44–12.79 oz/yd² common in denim styles.

- Test Stretch Recovery Performance: Apply AATCC or ISO methods to verify the fabric’s elasticity and ability to return to its original shape, with recovery rates ideally above 90% post-stretching.

Test Stretch

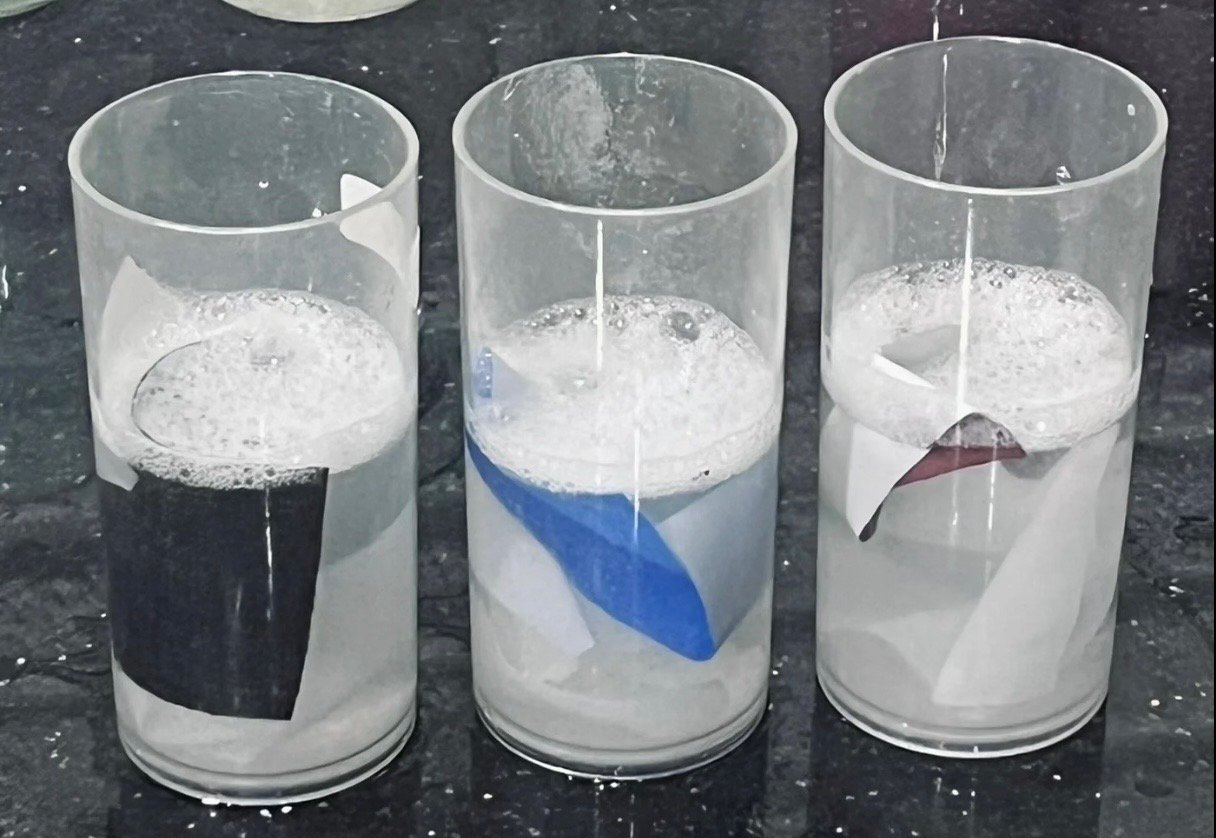

- Check Colorfastness: Perform washing tests to prevent fading, ensuring the denim retains its vibrancy over time. Standards require dry rubbing ≥ level 3-4 and wet rubbing ≥ level 3.

Check Colorfastness

- Detect Defects Early: Look for holes, stains, or weaving irregularities using visual and automated tools. Pareto analysis shows top defects like fabric deformity account for 31.53% of issues.

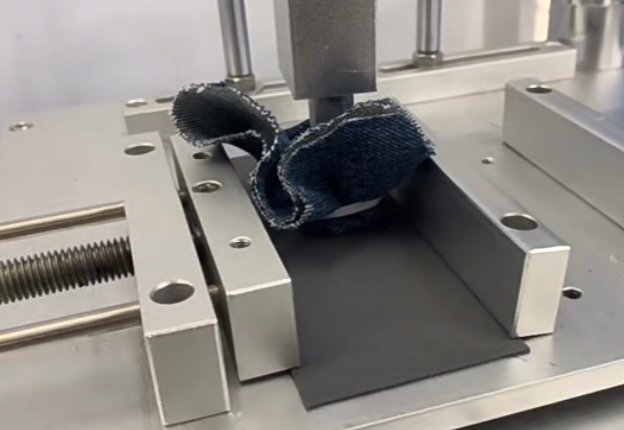

- Evaluate Tensile Strength: Measure how well the fabric withstands pulling forces, crucial for durable garments, with tear strength changes up to -40% after washes in heavily treated denim.

Tensile Strength

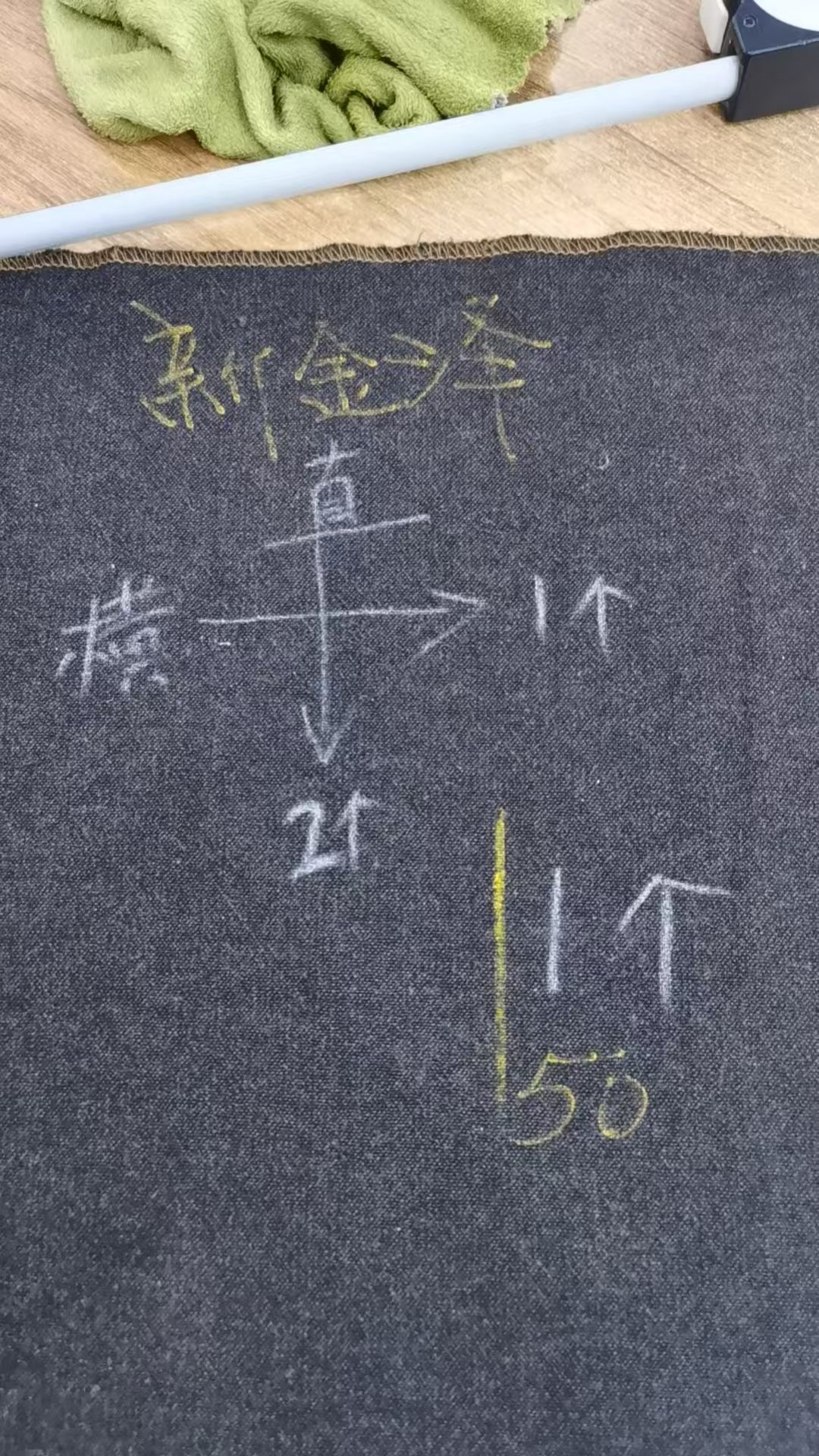

- Assess Shrinkage Resistance: Test under controlled conditions to minimize post-wash distortions. Shrinkage typically ranges from 1% in sanforized fabrics to 5–7% in raw denim, with tolerances at ±3%.

- Verify Fabric Texture: Ensure a smooth, comfortable feel that aligns with customer preferences.

Verify Fabric Texture

- Conduct Durability Tests: Simulate wear and tear to predict long-term performance, aiming for abrasion resistance of at least 17,000 revolutions.

Durability Tests

- Review Supplier Certifications: Confirm compliance with standards like denim fabric certification.

Review Supplier

- Implement Lean Principles: Reduce waste through just-in-time production and continuous improvement, targeting zero-defect levels via statistical process control.

By integrating these steps, garment factories can optimize their denim fabric quality control processes, leading to fewer customer complaints and higher satisfaction rates. For example, overall defect rates in denim production can drop from 5.67% with targeted interventions.

Implementing Denim Fabric Quality Control in Production Lines

Once your checklist is in place, focus on execution. Start with incoming inspections upon fabric arrival from suppliers. For example, partnering with reliable sources like those featured on lydenim.com can provide insights into best practices for sourcing and testing.

Incorporate automated systems for real-time monitoring during manufacturing. This enhances denim fabric quality control by flagging inconsistencies instantly. Additionally, train staff on protocols to maintain consistency across shifts, addressing the 63.2% human-error rate in defects.

For stretch denim, prioritize recovery testing to ensure garments like jeans maintain shape after repeated use. Finishing treatments, such as enzymatic bleaching or ozone washing, can further improve durability and aesthetics, while reducing water pollution impacts from denim processes, which account for 20% of global textile water pollution.

Control in Production Lines

Benefits of Strong Denim Fabric Quality Control

Effective denim fabric quality control yields numerous advantages. It reduces production costs by minimizing defects and rework. Factories achieve better regulatory compliance, avoiding penalties and recalls. Moreover, high-quality denim products foster brand loyalty, as customers appreciate comfortable, long-lasting apparel.

In the apparel industry, where trends evolve rapidly, maintaining superior standards sets you apart from competitors. Data from industry reports shows that factories with rigorous checks experience up to 30% less waste, directly impacting profitability. Additionally, proactive controls help mitigate the U.S. textile waste of 17 million tons annually, with only 15% recycled.

maintaining superior standards

Common Challenges and Solutions in Denim Fabric Quality Control

Despite best efforts, challenges like supplier variability or equipment limitations can arise. To counter this, conduct regular audits and diversify suppliers. Invest in training programs to empower your team with the latest testing methods, targeting the 68% of defects from top sewing processes.

For defect detection, advanced tools like laser scanners can enhance accuracy. If issues persist, refer to resources from experts in textile quality management for tailored advice.

Denim Fabric Quality Control

FAQs on Denim Fabric Quality Control

What is the role of denim fabric quality control in garment manufacturing?

It identifies defects early, ensuring products meet quality standards and reducing costs from fixes or discards, with defect rates potentially as high as 63.6% without it.

How does a checklist improve apparel production?

A denim fabric quality control checklist standardizes processes, minimizes errors, and ensures consistent high-quality output, cutting waste by up to 30%.

Why focus on fabric weight and stretch recovery?

Consistent weight ensures comfort, while strong recovery prevents sagging, extending garment lifespan amid shrinkage risks of 5-7% in raw denim.

For more on related topics, check our internal guides: Denim Sourcing Best Practices and Fabric Testing Methods. Explore external resources like the ASTM International standards for in-depth protocols.

Conclusion

mastering denim fabric quality control is key to thriving in the garment industry. By following this checklist and tips, factories can produce premium denim that delights customers and drives business growth. Start implementing these strategies today for noticeable improvements.