Exploring Weaving Patterns: From Plain to Neps

Estimated reading time: ~5 minutes

Introduction

Weaving patterns are the backbone of textile design, influencing the look, feel, and performance of fabrics. From the simplest plain weave to the more complex patterns like jacquard and neps, each type has its unique characteristics and applications. This blog will delve into eight key weaving patterns, providing insights into their properties and uses, based on 2025 textile knowledge.

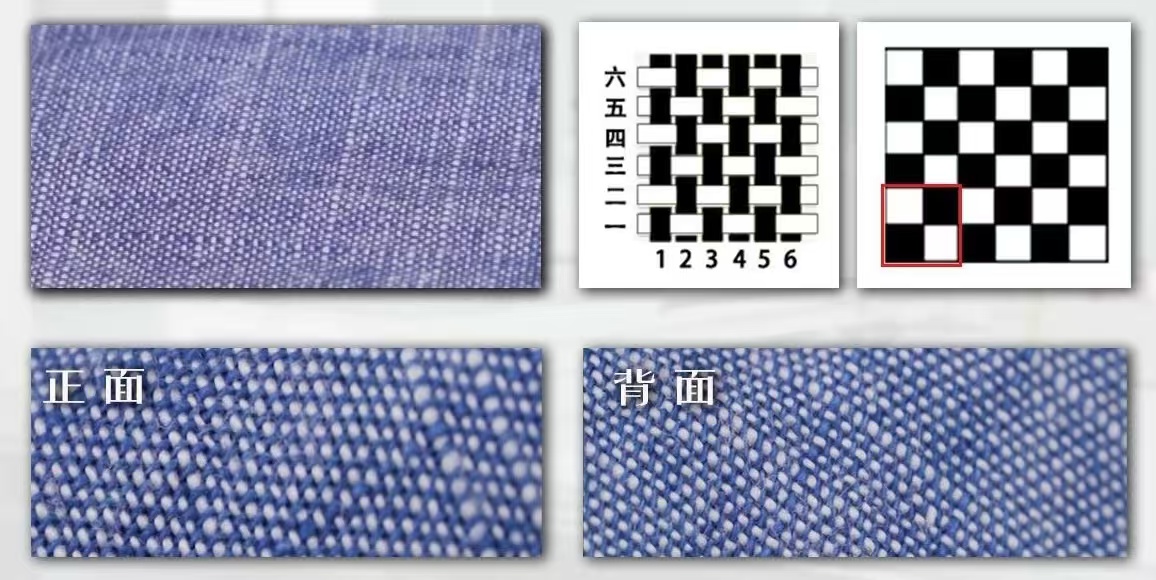

- Plain Weave Description: The most basic weave, with warp and weft yarns interlacing alternately, one over, one under. Properties: Flat, smooth surface; high number of interlacing points; relatively stiff; low elasticity; weak luster; mostly thin materials. Applications: Commonly used for casual shirts and youth cloth, especially in fabrics like denim that show a slightly wrinkled look after washing, ideal for casual wear. External Link: Learn more about plain weave

Plain Weave

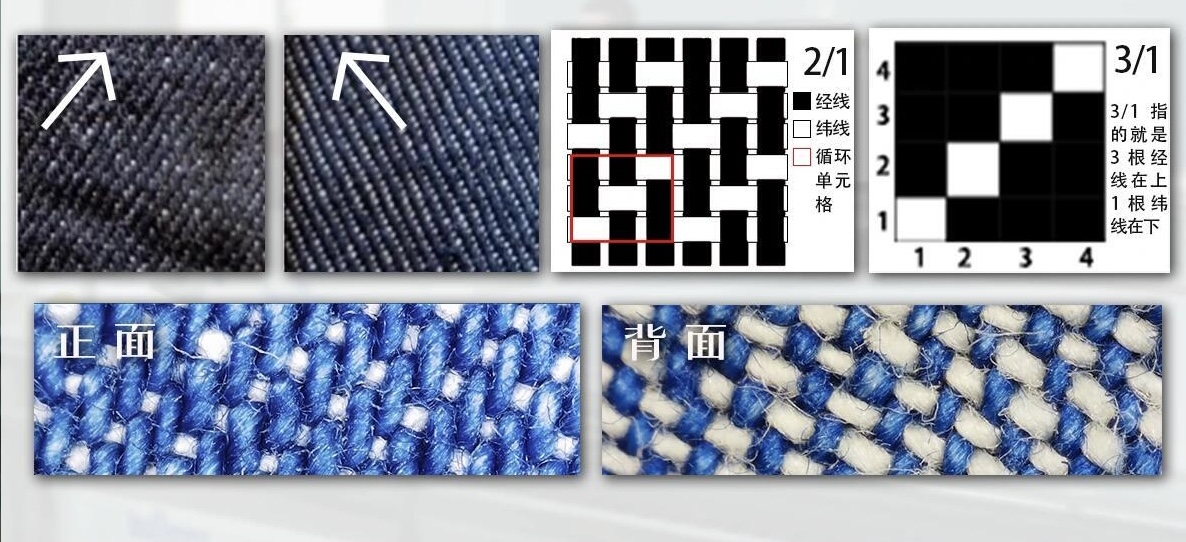

- Twill Weave Description: Warp and weft yarns interlace every two or three yarns, creating a diagonal pattern, with common types like 3/1, 2/1, and 2/2 twill. Properties: Diagonal texture, fewer interlacing points than plain weave, clear texture, significant difference between front and back, thicker and softer, good wrinkle resistance. Subtypes: Right twill (Z twill, diagonal from bottom left to top right) and left twill (S twill, diagonal from bottom right to top left), with left twill slightly softer and more voluminous. Applications: Pants, suits, and shirts, valued for durability and aesthetics. External Link: Explore twill weave

Twill Weave

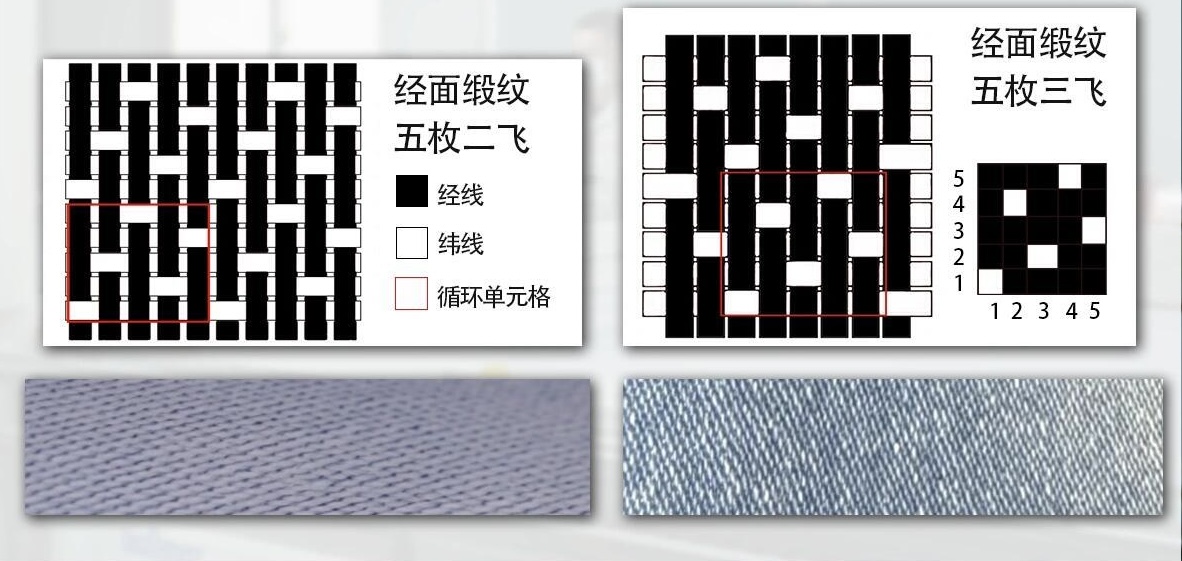

- Satin Weave Description: Warp and weft yarns interlace at intervals of four or more, with the surface primarily covered by warp yarns, often used in straight denim. Properties: Diagonal but discontinuous texture, few interlacing points, smooth and glossy surface, soft with good drape, prone to fuzzing and snagging due to long floats. Applications: Ideal for fitted, elastic, or skinny pants, emphasizing flexibility and shine. Technical Note: Terms like “end” (length and width of a repeating unit cell) and “pick” (number of weft yarns between interlacing points) are key, e.g., five-end two-up warp satin. External Link: Read about satin weave

Satin Weave

- Herringbone (Twill Derivative) Description: A variant of twill weave, creating a zigzag, fishbone-like pattern, symmetrical along a central axis. Properties: “V” or zigzag pattern, clear texture, three-dimensional and tactile, good wrinkle resistance and drape, reduces fabric distortion. Variations: Hand feel varies with yarn thickness and weave density; coarser yarns and denser weaves result in pronounced texture and stiffer structure, while finer yarns yield softer fabrics. Applications: Common in suits, jackets, and jeans, with historical roots tracing back to Roman times, originally used for road construction. External Link: Discover herringbone pattern

Herringbone (Twill Derivative)

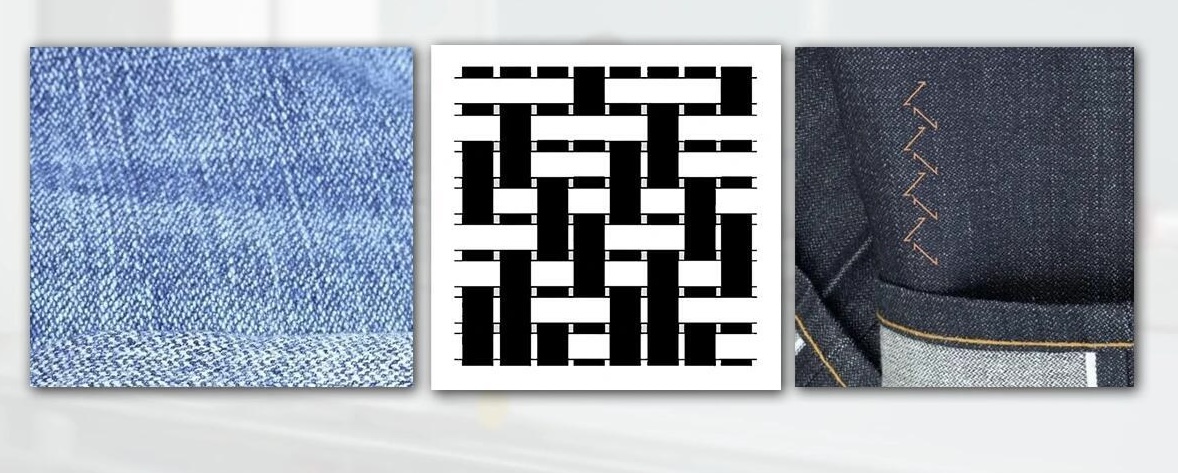

- Broken Twill Description: Combines right and left twill weaves, with weft yarns alternating left and right every two warp yarns, creating a disrupted zigzag or net-like pattern. Properties: No obvious directional pattern on the surface, similar hand feel and weight to 3/1 twill denim, reduces fabric distortion by breaking uniform stress, minimizing visible deformation after washing or shrinking. Applications: Used in denim fabrics to maintain shape and reduce shrinkage. External Link: For more, see general twill information

Broken Twill

- Jacquard (Dobby Weave) Description: A modern hybrid combining traditional denim design with Eastern jacquard techniques, allowing for varied patterns and designs. Properties: Can create various floral or geometric designs, smooth lines, highly versatile, with pattern complexity depending on the loom type. Types: Small jacquard (dobby, limited pattern variety, shows subtle same-color textures or dots), large jacquard (extensive pattern capabilities, ideal for casual wear), and embroidery jacquard (patterns embroidered directly onto the surface). Applications: Casual wear with visible textures, especially in denim. External Link: Learn about jacquard

Jacquard

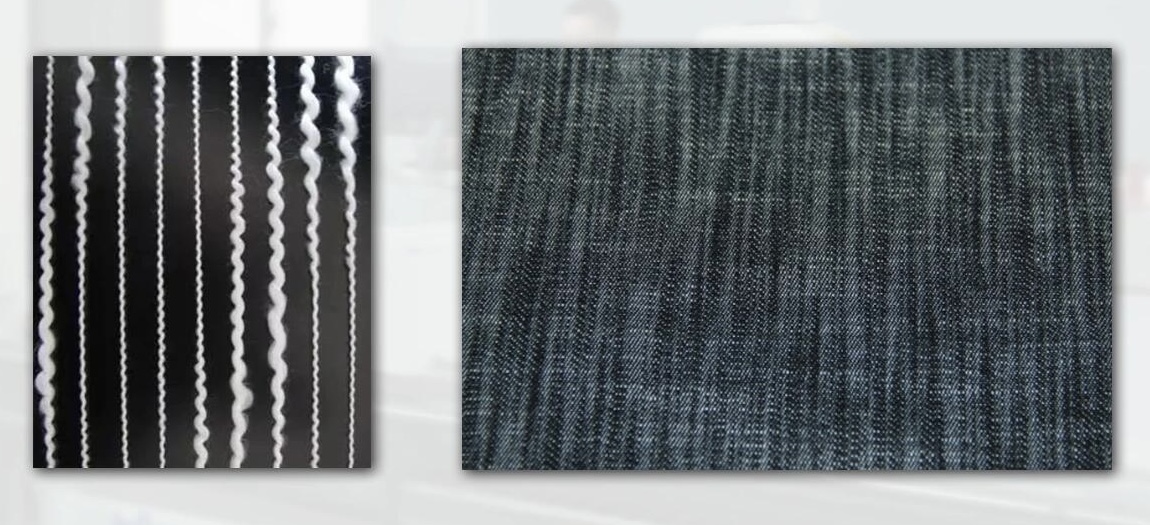

- Slub Texture Description: Originally a defect, now intentionally created by spinning yarns of varying lengths and thicknesses to mimic bamboo nodes, with raised white spots forming vertical streaks. Properties: Irregular texture, retro and textured look, can produce regular patterns like scattered raindrop, dense willow leaf, cloud, or hazy effects if spun consistently. Applications: Used in denim for unique vintage style, enhancing visual interest. External Link: Check slub yarn

Slub Texture

- Neps Texture Description: Previously a defect caused by impurities or uneven fiber length during carding, resulting in tangled cotton knots, now sometimes used for aesthetic effect. Properties: More pronounced than slub, with visible white fuzzy particles resembling snowflakes on denim, knots appear larger and clearer on the reverse side. Applications: Enhances texture and visual interest in denim, adding a unique aesthetic. External Link: Explore neps

Neps Texture

Comparison Table

Here’s a summary of the weaving patterns for easy comparison:

| Pattern Name | Texture | Interlacing Points | Hand Feel | Applications |

|---|---|---|---|---|

| Plain Weave | Flat, smooth | High | Stiff | Casual shirts |

| Twill Weave | Diagonal | Fewer than plain | Softer, thicker | Pants, suits |

| Satin Weave | Smooth, glossy | Few | Soft, good drape | Fitted pants |

| Herringbone | Zigzag, 3D | Fewer than plain | Textured, tactile | Suits, jackets |

| Broken Twill | No obvious direction | Similar to 3/1 twill | Similar to 3/1 twill | Denim |

| Jacquard | Varied, complex | Depends on pattern | Depends on pattern | Casual wear |

| Slub Texture | Raised spots, irregular | Irregular | Textured | Denim, vintage style |

| Neps Texture | Fuzzy particles, irregular | Irregular | Textured | Denim, enhanced texture |

Conclusion

Understanding weaving patterns is crucial for appreciating textile production’s art and science. Each pattern offers unique properties, from everyday clothing to specialized denim applications. As of 2025, weaving technology continues to evolve, with digital design tools and new materials enhancing patterns, though the classics remain vital.

Call to Action

We’d love to hear from you! Which weaving pattern is your favorite, and why? Share your thoughts in the comments below. Also, don’t forget to subscribe to our newsletter for more insightful articles on textiles and fashion. Contact us at malone@lydenim.com or visit www.lydenim.com for expert advice and tailored solutions.

Customization Services by LYDENIM

🎨 Want custom denim fabrics or unique custom denim garment? LYDENIM specializes in tailor-made solutions to meet your design and production needs.

🛍️ Explore & Get Inspired: Browse our fabric selections and discover design ideas on LYDenim.

🌐 Elastic Clothing: Check out our offerings on MyAlibaba. 📩 Contact Us: Reach out at malone@lydenim.com.

Create your denim masterpiece with LYDENIM—your trusted partner for stretch fabric and custom denim solutions.