Analysis of Denim Warp Yarn Types in Chinese Manufacturing

Estimated reading time: ~5 minutes

Introduction

China leads the world by manufacturing the most denim fabric which amounts to 1.5 billion square meters each year. The industry transitioned away from cheap manufacturing and towards creating valuable innovative products. The evolution of warp yarns includes OE Yarn, OE Soft Yarn, Siro Yarn and Super Soft Siro Yarn which serve both basic mass production needs and high-end premium markets. The article examines technical aspects alongside performance data and market patterns in detail for clear understanding.

Technical Characteristics and Material Composition

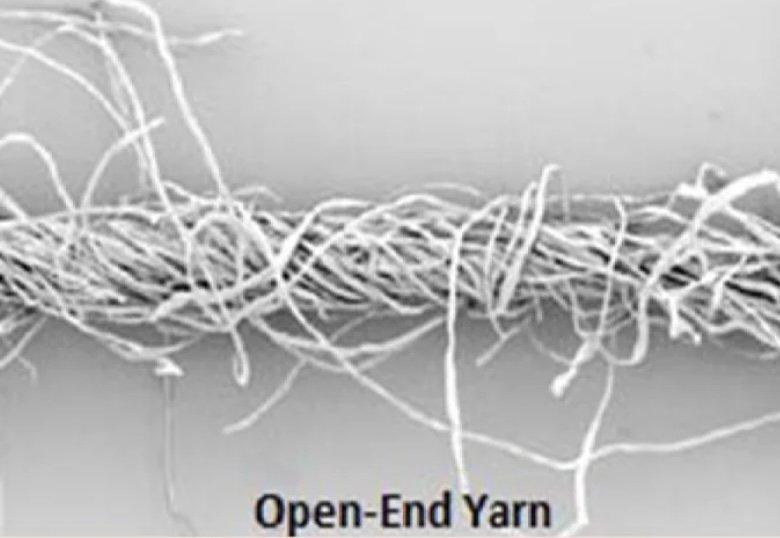

1. OE Yarn

-

Process: The high-speed rotor spinning process at 120,000 rpm creates a tight outer section that pairs with a loose inner section while the manufacturing speed reaches 100–150 m/min ten times faster than ring spinning.

-

Materials: The manufacturing process utilizes both carded cotton and short-staple cotton that has lengths under 38mm with an increasing addition of recycled cotton.

-

Performance:

-

The robust nature of this yarn produces a rugged texture with a complete hand feel.

-

The yarn displays exceptional resistance to wear (25,000 Martindale cycles).

-

The strength level of this yarn stands at 15-20% below ring-spun yarn strength.

-

-

Applications: Fast fashion and workwear products consume more than 70 percent of the market.

2. OE Soft Yarn

-

Process: The manufacturing process starts with OE spinning followed by cleaning the fibers and then carding them into uniform slivers. The rotor spinning process transforms fibers into yarns through fast twisting operations. The combination of softer fibers or blended materials together with reduced twisting levels and post-finishing treatments including singeing or chemical softening methods creates a more delicate touch.

-

Performance:

-

Smooth, soft hand feel with low hairiness.

-

This yarn material demonstrates exceptional air permeability and moisture retention capabilities which make it perfect for clothing products that touch the skin such as baby clothes and home textiles.

-

This yarn exhibits reduced tensile strength than regular OE yarns but maintains good abrasion resistance although it performs worse than ring-spun yarns.

-

-

Drawbacks:

-

High twist reduces yarn strength making it unsuitable for demanding applications.

-

Higher production costs due to additional processing.

-

Some finishes may compromise breathability.

-

-

Applications: Mid-range comfort-focused denim and eco-friendly lines.

Open-End Yarn

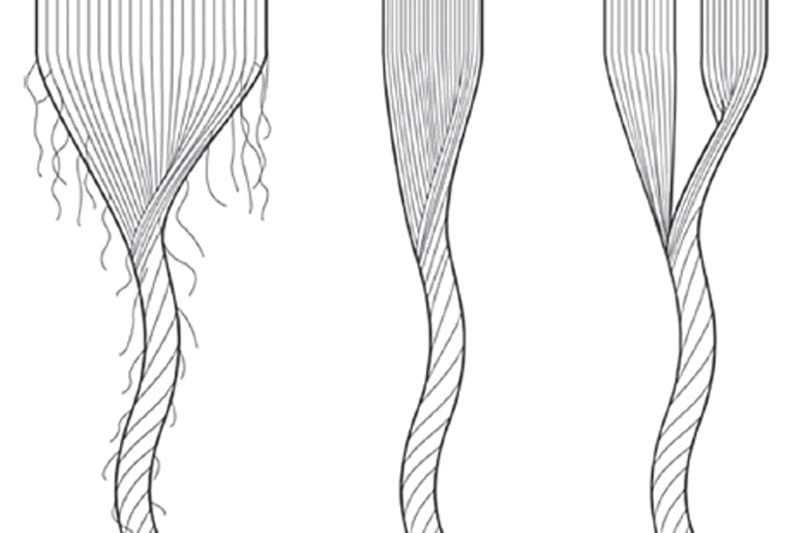

3. Siro Yarn

-

Process: Dual roving feed with synchronized twisting forms a strand-like structure.

-

Performance:

-

60% less hairiness (≤25 hairs/10m for 3mm+ fibers).

-

30% higher strength than OE yarn, suitable for high-tension weaving.

-

Supports 2–5% spandex for 20–25% weft elasticity.

-

-

Applications: Mid-to-high-end denim, such as 3/1 twill, with clear textures.

4. Super Soft Siro Yarn

-

Process: Based on Siro spinning, two rovings are fed into the drafting zone, merged, and twisted. Softness is enhanced by lower twist, long-staple cotton, or bamboo fiber blends, often combined with compact spinning for uniformity.

-

Performance:

-

Exceptionally soft, smooth, and fine, with excellent moisture absorption and wash durability.

-

Low hairiness and high abrasion resistance, ideal for skin-contact products like baby sleepwear and lingerie.

-

-

Drawbacks:

-

Potential yarn unevenness and thin spots in fine counts.

-

Higher breakage rates may reduce production efficiency.

-

-

Applications: Luxury denim and premium comfort products.

Comparative Performance Metrics

|

Yarn Type |

Breaking Strength (cN/tex) |

Hairiness Index (hairs/10m) |

Material Cost (CNY/kg) |

Fabric Weight (oz/yd²) |

|---|---|---|---|---|

|

OE Yarn |

8.5–10.2 | 120–150 | 18–22 | 12–16 |

|

OE Soft Yarn |

11.3–13.5 | 90–110 | 32–38 | 8–12 |

|

Siro Yarn |

14.2–16.8 | 20–35 | 35–42 | 10–14 |

|

Super Soft Siro Yarn |

13.5–15.7 | 15–25 | 48–55 | 7–10 |

Advantages, Challenges, and Market Positioning

OE Yarn: Cost-Driven Leader

-

Advantages:

-

High efficiency, 10x faster than ring spinning.

-

Low material costs, suitable for low-grade or recycled cotton.

-

-

Challenges:

-

Lower strength limits use in heavy fabrics.

-

Rough hand feel requires post-finishing.

-

-

Market: Mass-market denim, >70% share.

OE Soft Yarn: Eco-Friendly Upgrade

-

Advantages:

-

Tencel blends offer superior comfort and moisture absorption.

-

15% better indigo dye uptake, with color fastness of 4–5.

-

-

Challenges:

-

45% higher Tencel costs increase overall expenses by 50%.

-

Requires optimized processing to prevent fiber damage.

-

-

Market: Mid-range eco-conscious lines (e.g., H&M Conscious), 15–20% premium.

Siro Yarn: Quality-Driven Choice

-

Advantages:

-

Low hairiness and clear fabric texture.

-

Supports fine counts (21S–32S) for lightweight denim.

-

-

Challenges:

-

High equipment costs (CNY 2M for 10,000 spindles).

-

25% slower production than OE yarn.

-

-

Market: Mid-to-high-end brands (e.g., Armani denim).

Super Soft Siro Yarn: Luxury Benchmark

-

Advantages:

-

Ultra-soft, smooth, and durable, ideal for skin-contact applications.

-

Low hairiness and high wash durability.

-

-

Challenges:

-

Yarn unevenness and breakage risk in fine counts.

-

Higher costs and complex production.

-

-

Market: Premium and luxury denim segments.

Experimental Data and Market Validation

Performance Testing

-

Abrasion Resistance (ASTM D4966):

-

OE Yarn: 25,000 cycles before pilling.

-

Siro Yarn: 50,000 cycles, doubling lifespan.

-

-

Shrinkage Control:

-

OE Yarn: 3–5% shrinkage after washing.

-

Super Soft Siro Yarn: ≤3% post-preshrinking, with <3% fabric skew.

-

-

Environmental Impact:

-

Tencel blends: 35% lower carbon emissions, 50% less water usage.

-

Market Trends

-

Athleisure Demand: Siro yarn with 2–5% spandex achieves 20–25% elasticity.

-

Lightweight Fabrics: Super soft yarns enable <8 oz/yd² fabrics, with 15% annual growth in summer products.

-

Fast Fashion: OE yarn’s 3-day lead time vs. Siro yarn’s 7 days supports rapid supply chains.

Conclusion

The warp yarn sector in China’s denim industry maintains a dynamic equilibrium between cost performance and sustainable quality production. The mass market depends on OE yarn because it provides efficiency at an affordable price yet the OE soft yarn meets the needs of environmentally aware consumers by offering better comfort features. The mid-to-high-end markets benefit from Siro yarn and super soft Siro yarn because these materials deliver exceptional strength alongside better texture and superior softness. The changing consumer preferences toward sustainable elastic lightweight fabrics require manufacturers to adopt advanced spinning technology along with eco-friendly materials including Tencel. Manufacturers need to achieve production cost-quality balance while using automated systems to eliminate production defects and comply with worldwide sustainability standards for capturing high-value markets.

Customization Services by LYDENIM

🎨 Want custom denim fabrics or unique custom denim garment? LYDENIM specializes in tailor-made solutions to meet your design and production needs.

🛍️ Explore & Get Inspired: Browse our fabric selections and discover design ideas on LYDenim.

🌐 Elastic Clothing: Check out our offerings on MyAlibaba. 📩 Contact Us: Reach out at malone@lydenim.com.

Create your denim masterpiece with LYDENIM—your trusted partner for stretch fabric and custom denim solutions.

Your ability to distill complex concepts into digestible nuggets of wisdom is truly remarkable. I always come away from your blog feeling enlightened and inspired. Keep up the phenomenal work!

I have read some excellent stuff here Definitely value bookmarking for revisiting I wonder how much effort you put to make the sort of excellent informative website