Comprendre le filage du denim : de l'histoire à la création du fil

Introduction: The Art of Spinning in Denim Production

Spinning is the heart of denim fabric creation, transforming raw cotton fibers into the durable yarn that defines your favorite jeans. Whether you’re curious about “what is denim fabric” or “how is denim made,” it all begins with spinning. In this post, we’ll explore the spinning process, its history, and the techniques that shape denim’s unique texture—ring spinning and open-end spinning. Let’s dive into the world of yarn and discover how it’s crafted!

1. Spinning Explained: The Foundation of Denim Fabric

Spinning is the process of twisting fibers into yarn, a critical step in producing denim fabric. This yarn becomes the warp and weft threads woven into the sturdy material we know as denim. The process involves two stages: preparation, where fibers are aligned and elongated, and spinning, where they’re twisted into yarn.

Fibres de coton préparées pour le filage

2. How Yarn is Spun: From Cotton to Denim

The journey starts with cotton bales. A bale plucker extracts fibers, which are cleaned and mixed. Next, the carding machine parallelizes them into a fluffy “sliver.” This sliver is elongated further in the drawing frame, combining multiple slivers for strength. Finally, torsion twists the fibers into yarn

Plumage des balles

3. Yarn Count: Measuring Denim’s Thickness

Yarn count, or “Ne,” measures yarn thickness by mass per unit length. Denim typically uses Ne 4 to Ne 20—lower numbers mean thicker yarn, ideal for rugged jeans. For example, “7×7 denim” indicates the yarn count for warp and weft. where thickness impacts fabric weight and feel.

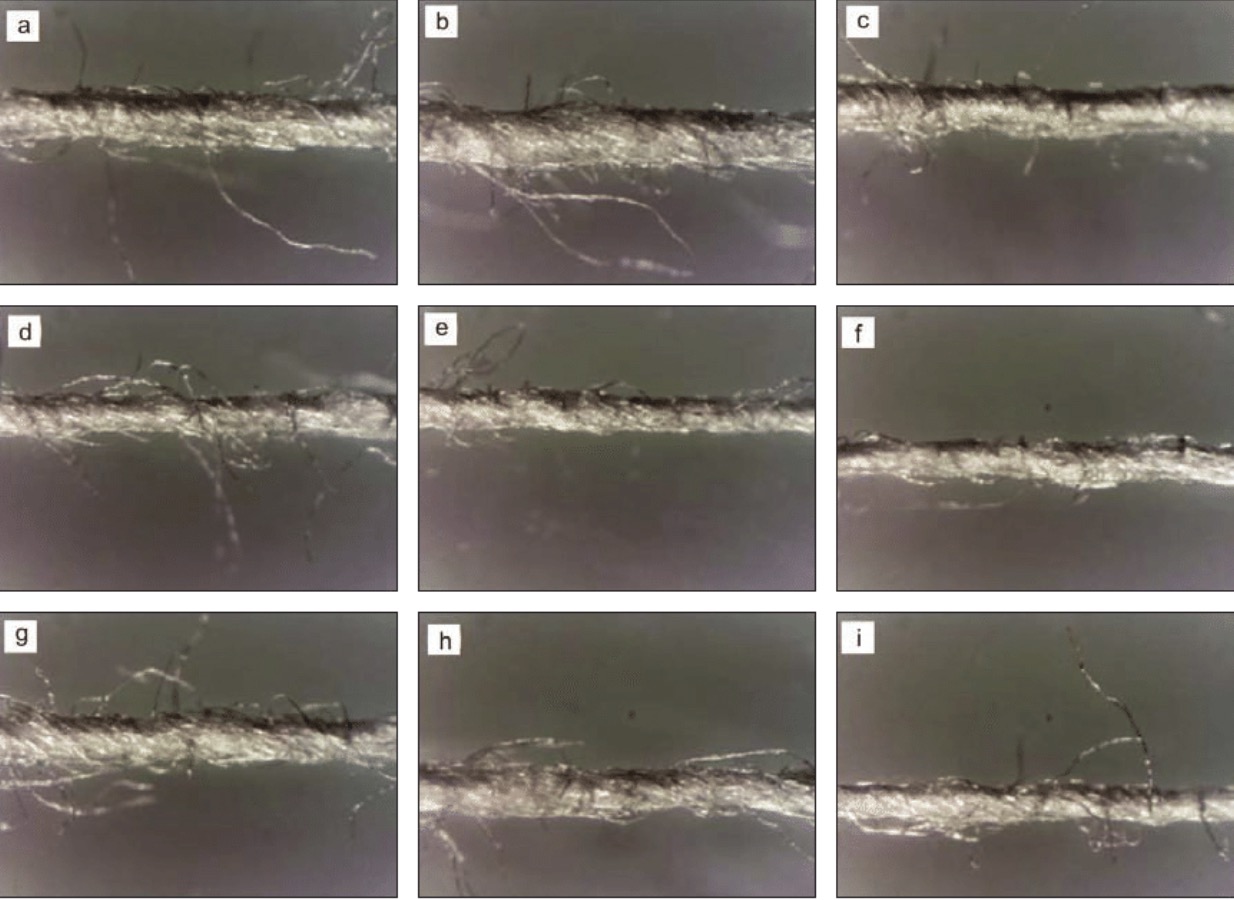

Yarn samples spun in different counts and nozzle pressures

4. Roving: Preparing for the Spin

Roving is a key preparation step in ring spinning. Slivers enter roving frames, where initial torsion thins them into a ribbon, ready for final twisting. This stage enhances yarn durability, crucial for “stretch denim fabric” (480 searches), blending cotton with elastomers for comfort.

flammé

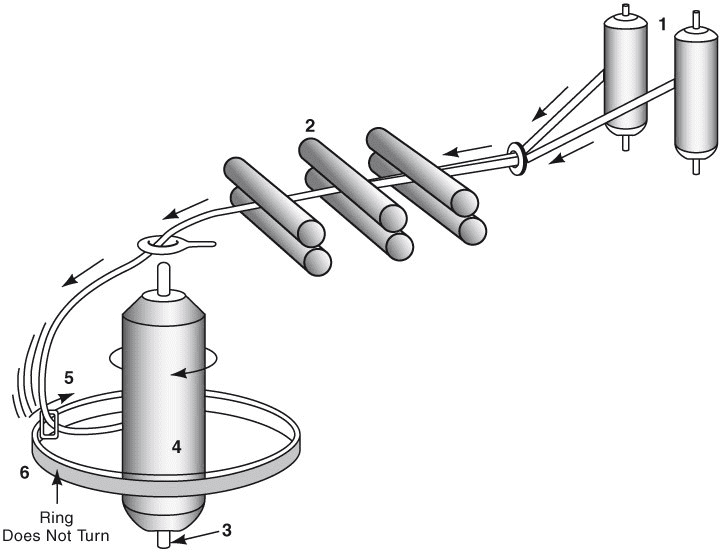

5. Filature d'anneaux: The Classic Denim Method

Ring spinning, invented in 1828, twists yarn using a rotating spindle, ring rail, and traveller. It produces soft, durable yarn with natural slubs—perfect for “authentic” denim. Its resurgence, driven by stretch denim demand (e.g., “stretch denim fabric”), reflects its versatility.

Filature à anneaux

6. Open-End Spinning: The Modern Alternative

Introduced in 1963, open-end (rotor) spinning is faster and cheaper, using air and a rotor to twist fibers. However, it creates uniform yarn without slubs, less ideal for high-contrast fades. It can’t produce stretch yarn, limiting its use despite efficiency.

7. The History of Spinning: From Hand to Machine

Before the Industrial Revolution, spinning was manual. Ring spinning emerged in 1828, dominating denim until open-end spinning took over in the 1970s. Today, ring spinning leads again, fueled by authenticity trends.

Conclusion: Why Spinning Matters to Denim Lovers

Spinning shapes denim’s look, feel, and durability. Whether it’s the rugged charm of ring-spun yarn or the efficiency of open-end spinning, understanding this process deepens your appreciation for denim fabric. Want to explore premium denim options? Visit lydenim.com ou contactez Malone@lydenim.com for more insights!