Unraveling the Art of Denim: How Ring Spinning Shapes Your Favorite Jeans

Estimated reading time: ~5 minutes

Introduction: The Journey of Denim Fabric

Denim is more than just a fabric—it’s a lifestyle. From rugged workwear to stylish stretch jeans, denim’s versatility stems from its unique production process. Have you ever wondered, what is denim fabric made of or how denim is made? At the heart of this process lies ring spinning, a technique that crafts the yarn giving denim its strength, texture, and comfort. Let’s dive into how ring spinning works and why it matters for your jeans.

What Is Ring Spinning?

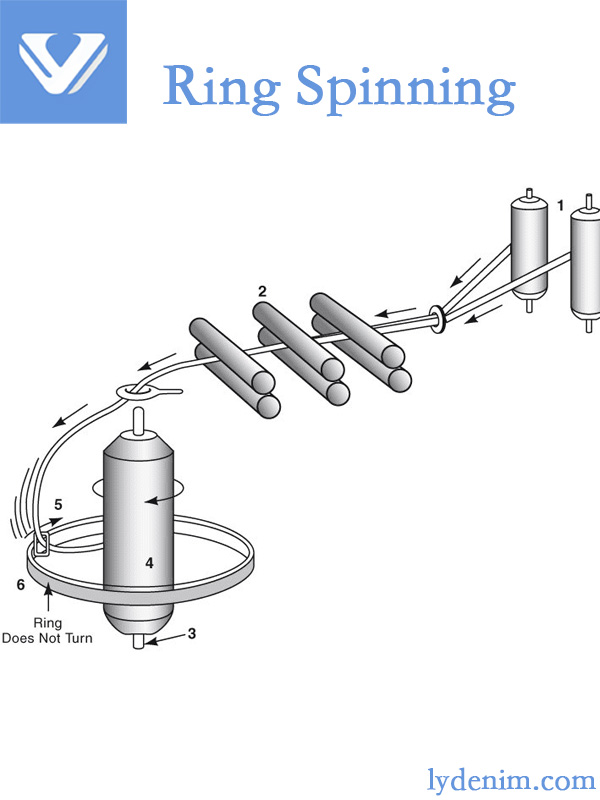

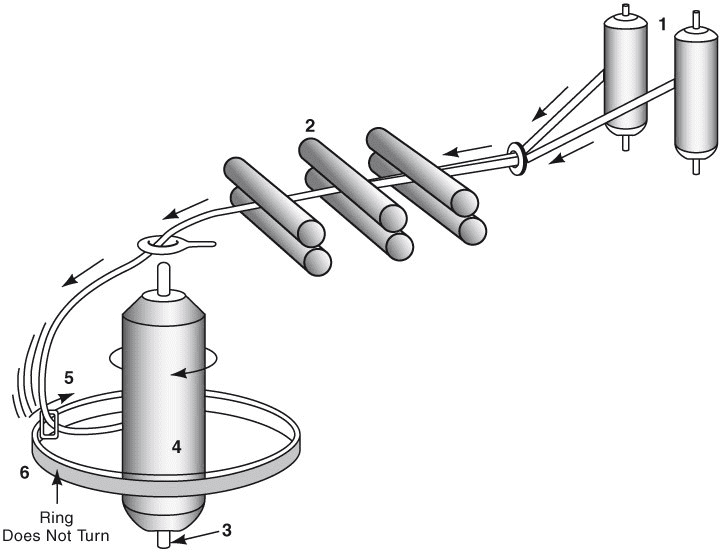

Ring spinning is a traditional yarn-making method that transforms raw cotton into the durable threads used in denim fabric. Here’s how it happens:

-

Starting with Slivers: The process begins with slivers—loose bundles of cotton fibers—wound onto bobbins. These slivers are fed into roving frames, where they get their first twist.

-

Drafting Rollers: The slivers then pass through drafting rollers, which stretch and thin them into a ribbon-like form, preparing them for more twisting.

Ring spinning

-

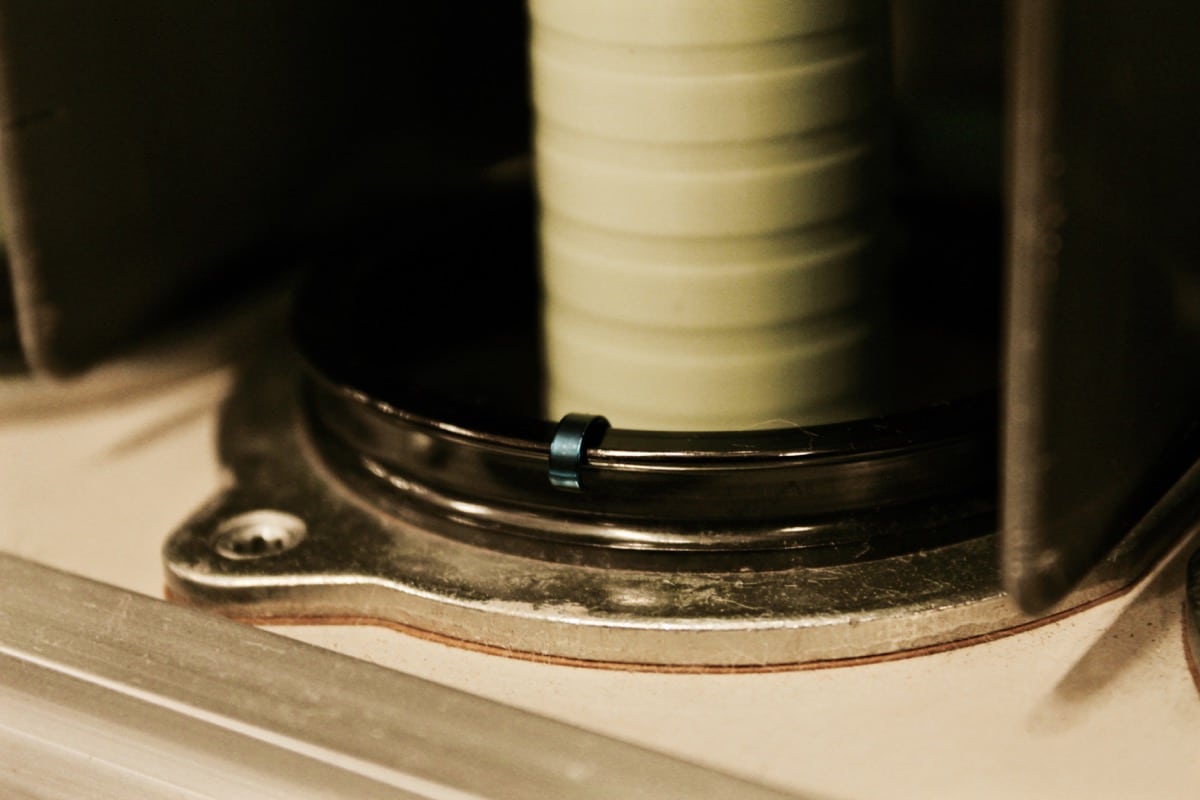

The Ring and Traveller Magic: The real twist (literally!) comes from the rotating spindle, encircled by a ring rail. A small clip called the ring traveller slides around the ring, twisting the yarn further as the spindle spins. This step defines the yarn’s strength and texture.

The ring and the ring traveller (the little blue clip)

-

Winding the Yarn: As the ring rail moves up and down, the twisted yarn is neatly wound onto a bobbin, known as the ring cop, ready for weaving into denim.

Why Ring Spinning Matters for Denim

Ring spinning isn’t just a process—it’s an art. Unlike other methods, it produces yarn with a unique combination of strength and softness, ideal for denim fabric by the yard. This technique ensures the cotton fibers are tightly twisted, giving denim its signature durability and ability to fade beautifully over time—perfect for that worn-in look we all love.

Stretch Denim: Adding Comfort with Ring Spinning

Want jeans that move with you? That’s where stretch denim fabric comes in. By adding a synthetic elastomer (like spandex) during the ring spinning process, the stretch is embedded into the yarn’s core, with cotton wrapped around it. This keeps the soft, breathable feel of cotton while adding flexibility.

- Pros: Enhanced comfort and fit, especially for skinny or slim jeans.

- Cons: Stretch denim may wear out faster than 100% cotton denim and can lose shape over time.

From Yarn to Jeans: The Bigger Picture

Once the yarn is spun, it’s woven into denim fabric, often using a twill weave for that classic diagonal pattern. Whether it’s selvedge denim fabric or lightweight options, ring-spun yarn ensures quality. Curious about how to soften denim fabric? Washing with fabric softener or vinegar can help, but the yarn’s initial softness from ring spinning sets the foundation.

Conclusion: Discover Denim Done Right

Ring spinning is the unsung hero behind your favorite jeans, blending tradition with innovation. Whether you’re after rugged denim or stretchy comfort, this process shapes the fabric’s soul.

Customization Services by LYDENIM

🎨 Want custom denim fabrics or unique custom denim garment? LYDENIM specializes in tailor-made solutions to meet your design and production needs.

🛍️ Explore & Get Inspired: Browse our fabric selections and discover design ideas on LYDenim.

🌐 Elastic Clothing: Check out our offerings on MyAlibaba. 📩 Contact Us: Reach out at malone@lydenim.com.

Create your denim masterpiece with LYDENIM—your trusted partner for stretch fabric and custom denim solutions.